Antistatic linoleum is a floor covering made of polyvinyl chloride, which has antistatic properties that prevent static charges from friction and contact with the material.

This type of building material is used in residential or industrial premises where excessive electrification occurs. Stacking helps reduce the risk of fires or explosions, reduces the amount of dust collected, eliminates the negative impact of static on precision instruments.

Specifications

When buying material, you need to check that the composition does not contain heavy components with abrasive particles, but only fiberglass. Antistatic coating has the following technical parameters:

Specifications

Specifications

- excellent insulator having high resistance and low conductivity,

- the possibility of laying in places with any humidity,

- high strength and uniformity, thanks to a thickness of up to 5 mm,

- increased wear resistance

- good elasticity

- excellent heat insulator

- high resistance to UV rays.

The latter characteristic is important when using material in industrial buildings. It should also be noted that such linoleum can be laid on a warm floor. The positive characteristics include the fact that it is immune to oils, fats and resins.

Varieties

All linoleums with antistatic properties are divided into:

- antistatic

- current-scattering,

- conductive.

Varieties

VarietiesOften all these species are mistakenly called by one common name - antistatic flooring. However, these types of material have a significant difference not only in the parameters, but also in the manufacturing and laying process.

So, the first type can be used in ordinary rooms, whereas for rooms with high-precision equipment (laboratories, automatic telephone exchanges, etc.) it is better to give preference to the third type. When choosing a coating, you should consult a specialist who will help you choose the right linoleum for a certain type of room.

Antistatic material

The coating has an electrical resistance of at least 10 9 Ohms. When walking on this floor, the voltage should be no more than 2 kV. Another name is insulating. It should be noted that any commercial linoleum is endowed with antistatic properties. In the absence of increased requirements for material for the floor, it can be laid everywhere. This type of coverage is used in call centers and classes with computer equipment.

Medical facility coverage

Medical facility coverage

Current-scattering

The resistance of this type of linoleum is 10 6 -10 8 Ohms. A special composition is obtained by introducing components (carbon or carbon filaments) that give the material current-scattering properties. When using such material, walking on it is not dangerous, since a possible static charge is dissipated. Apply such flooring in server rooms, X-ray rooms.

Technology for laying antistatic linoleum

Before laying the antistatic linoleum, you need to have a well-prepared, even base. High demands are made on the floor base, because due to the presence of flaws and defects, the flooring can become unusable.

Mounting

Mounting

The laying process itself is identical to the flooring of simple linoleum. A distinctive feature is only grounding, which must be connected to the coating.

The roll is left in the room for a while, so that it gets used to the temperature regime where the flooring will be made.

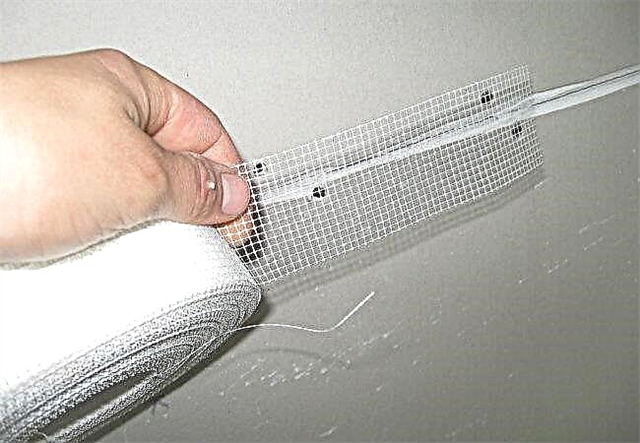

For laying grounding, a copper tape is used, which is laid out in the form of a grid. Then a special glue is applied, which is applied in a thin layer on copper strips and allow time to dry out a little.

The floor covering is laid entirely on conductive glue and is rolled with a roller to remove possible air bubbles.

Styling process

Styling process

If you need to make an incision in the process, then this is done carefully so that the insulation strip underneath remains intact.

After completion of work, it is necessary to check the floor for its ability to absorb electric charge. Inspection is carried out six months after installation, and if the coating does not match the results, it must be replaced.

Non-compliance with technical parameters may be caused by improper installation of the material. Therefore, only competent specialists need to trust laying of antistatic linoleum.

Major manufacturers and brands

Finding such coverage in stores is not difficult. It is more difficult to choose a really high-quality material, the technical characteristics of which clearly correspond to the requirements of GOST. Therefore, give preference to purchases in a store or mall where you can request a quality certificate from the seller.

Linoleum manufacturer Tarkett

Linoleum manufacturer Tarkett

Among all manufacturers, several brands can be distinguished that produce materials with excellent performance characteristics. These include:

The coatings of these manufacturers have certificates confirming the quality, and also meet all the requirements for the neutralization of electric charges. In the building materials market, Tarkett antistatic linoleum is available in three models:

IQ Granit Sd linoleum is a homogeneous coating with current-scattering properties. They are laid in places where effective electrical protection is needed.

Tarkett iQ Granit Sd Coating Model

Tarkett iQ Granit Sd Coating Model

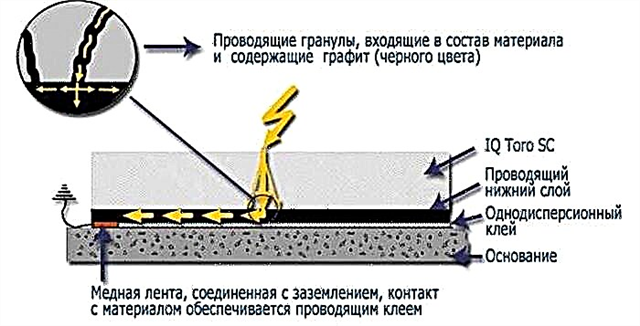

IQ Toro Sc linoleum is the highest-class coating with a protective layer based on polyurethane, which prevents the appearance of a static charge.

Linoleum Aczent Mineral As - provides an excellent antistatic effect.

Where to use

The area where antistatic linoleum with copper stripes is used is quite wide. It is used where there is a lot of equipment that is sensitive to electrical effects. These are such premises as:

- laboratories

- computer centers

- ultrasound, MRI,

- operating

- objects with explosive substances,

- rooms with high-precision equipment.

Antistatic coating in the cabinet

Antistatic coating in the cabinetAntistatic linoleum is increasingly being bought for apartments and houses, where there are many household appliances and appliances that produce a static charge.

When a person comes in contact with an electric device, a discharge sometimes occurs that is felt by a person. In turn, such a discharge negatively affects the technique itself, contributes to the attraction of dust. Therefore, it is linoleum with antistatic properties that will help to cope with such problems.

Advantages and disadvantages

Antistatic coating has a sufficient number of advantages. One of the main advantages is its versatility. It can be laid not only in apartments and houses, but also in offices, warehouses, industrial buildings. The absence of harmful chemicals in the composition, along with forbo marmoleum, give it high safety and hygiene indicators, which allows it to be laid even in bedrooms and kindergartens.

Among the advantages can be noted high moisture resistance. Good thickness of the material gives it high heat and sound insulating characteristics, as well as resistance to stress. In terms of durability, it is not inferior to the operational parameters of tiles or marble, which allows it to be laid in rooms with high traffic.

Another plus is that dust does not accumulate on the surface, it is easy to clean and wash. Resistance to chemicals and sunlight can preserve a presentable appearance for a long time.

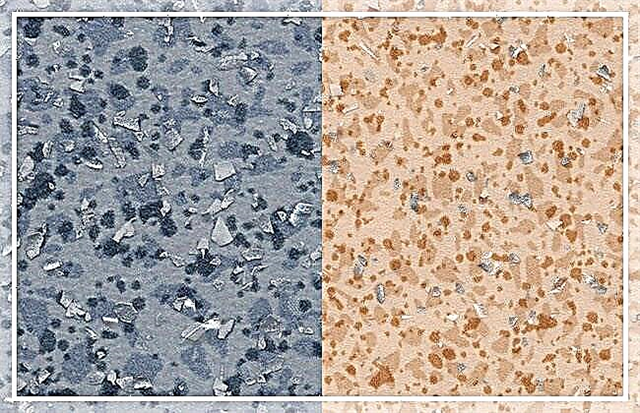

Antistatic coating has a wide variety of colors, designs and sizes.

There are different colors.

There are different colors.

The disadvantages include: the need for an even foundation for laying, a special non-eco-friendly composition, the high price of the coating.

Based on the foregoing, we can say that the antistatic coating is a fairly popular material that can be used in production, at home and in the office.

Features of antistatic floors: 1 feature

By and large, almost any PVC-based flooring is insulating and to some extent prevents the accumulation of static electricity on the surface. This means that in everyday life the characteristics of such materials can be considered quite sufficient for effective protection against free currents.

However, in rooms where a large amount of electronics or other electrical equipment is located, the situation is radically changing. The properties of ordinary linoleum are clearly not enough for efficient operation, and therefore antistatic linoleum is laid in such rooms - a special material that prevents the formation of residual stress.

Previously, rubber mats and rubber-based roll mats were used instead.

In some places they are used today, but modern antistatic polymer raw materials are gradually replacing rubber: the material looks better, it is easier to assemble, and it works no less efficiently.

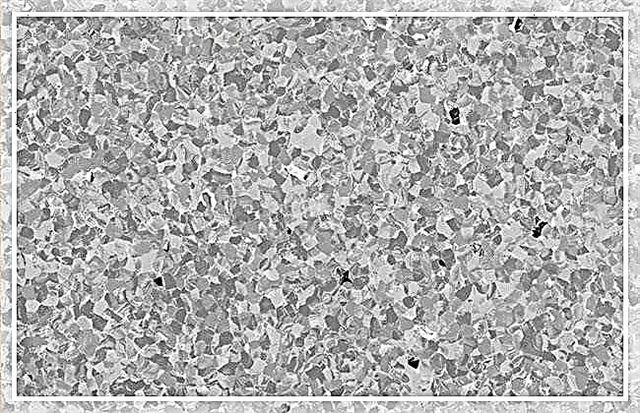

The coating palette is limited, but there is still something to choose from.

Externally, such coatings practically do not differ from ordinary linoleum, except that their palette is much poorer, since they are mainly intended for commercial use. Key differences are in the structure of the material.

The most important components are:

What is it and where is it used

Antistatic linoleum is a PVC-based floor covering interspersed with carbon filaments that dissipate or discharge static charges. Tarkett antistatic coating is available in the same colors as the regular linoleum of this company.

Such flooring is used in:

- computer labs

- laboratories

- dispatching

- server

- PBX premises

- physiotherapy rooms

- operating

- MRI rooms

- X-ray rooms,

- rooms where combustible and explosive substances are stored and used.

The properties of antistatic coatings are regulated by GOST and standards EN 1081 and EN 1815, BS, ASTM.

Room requirements

In the room where the antistatic linoleum will be laid, a temperature of at least +18 degrees and a humidity of 30-60% should be established. Before laying, linoleum is straightened, it can not be bent or folded. He must lie down for some time in the room in order to acquire room temperature.

The base must be dry, clean and even. Defects are eliminated by applying a layer of putty. There should be no traces of paint, asphalt, oil, ink or other contaminants on the substrate that can reduce the adhesion of the coating to the substrate. In addition, such substances can change the color and other characteristics of linoleum. The wood substrate should have a moisture content of not more than 8%. If the base has a high absorption capacity, then it must be coated with a primer and dried well.

The maximum temperature at which this coating can be used is 27 ° C, so it is important to check that the room temperature does not exceed this mark. This is especially important in rooms located above boiler rooms and boiler rooms. Antistatic linoleum is not intended for use in high humidity.

Stacking

The first stage is marking the coating. To do this, measure the room and calculate how many sheets are needed. Lines are applied to the sheets along which linoleum will be cut. Cutting can be done with a knife or scissors. Lines are best applied with a simple pencil, as pens or markers can change the color of the coating.

For laying antistatic linoleum conductive glue and copper tape are required. The latter performs the function of grounding. A grid of copper tape is laid on the base and glued with a special glue that does not contain neoprene.

Strips of copper tape are placed parallel to the joints of linoleum. It is important that all grounding parts are interconnected.

After laying the ground, the linoleum sheet is glued. To do this, glue is applied to the base and copper tapes, a coating is laid on top and pressed. Each strip is ironed with a smooth roller with a weight of at least 65 kg. Joints of canvases are brewed, I use a cord for welding linoleum. Before welding, the edges of the sheets are chamfered by 2/3 of the thickness.

If you need to cut holes in the linoleum for pipes or other elements, this is done carefully so as not to damage the copper mesh. A copper grid is also needed to measure the resistivity of the floor.

During cleaning, the antistatic linoleum is first swept away, removing debris and large particles, then washed. When washing this floor, you need to be careful so as not to damage the polyurethane coating. Do not use detergents to clean the floor, it is best to use special detergents or clean water.

Antistatic coatings are a means of protection that cannot be dispensed with in rooms with high-precision equipment that are subject to the effects of static electricity. Depending on the purpose, they may have different resistance. Such coatings are subject to high requirements in terms of strength, fire safety, and hygiene indicators.

Types of paintings

Linoleum with an antistatic effect is divided into three groups:

- Antistatic coatings forming a voltage of not more than 2 kW. The minimum resistance is 109 ohms.

- Current-scattering, having a resistance of 106-108 Ohms. In order for the current-scattering linoleum to fulfill its main function, carbon particles or threads are included in the composition, due to which the electric charges that arise during movement instantly dissipate over the entire surface, becoming completely harmless.

- Conductive, with special graphite additives that provide flawless conductivity, resulting in lightning-fast removal of charges from the surface. Such linoleums have a resistance of at least 104 ohms.

The scope of application of antistatic PVC coatings is private houses, assembly electrical workshops, power plants, computer labs, laboratories, medical facilities, in particular, operating units, ultrasound / MRI rooms, X-ray rooms, etc., where it is necessary to minimize the accumulation of electric charges .

Advantages and disadvantages

The undoubted advantage is versatility. Antistatic linoleum is successfully applied both in houses / apartments, and in production shops.

High safety and hygiene indicators are due to the absence of heavy chemicals in the composition, which allows its installation in children's institutions and bedrooms. And excellent moisture resistance significantly expands the range of use.

Sufficient thickness of the product provides good heat and sound insulation parameters, resistance to various mechanical loads. The durability is comparable with the life of tiles and marble, as a result of which it can be easily laid even in rooms with excessive load intensity.

Inability to accumulate dust greatly simplifies the process of maintenance, and high resistance to chemical compounds and phenomenal color-fast parameters will help to maintain a presentable appearance for a long time.

Antistatic PVC linoleum is available in a huge range of colors and textures. In addition to traditional rolls, it is made in the form of tiles with a pattern for a laminate, parquet board and other finishing materials.

The main disadvantages are: non-ecological composition, the possibility of laying only on a prepared (leveled) base and high cost.

Selection tips

When choosing an antistatic linoleum, it is necessary to take into account its class. A thicker protective layer corresponds to a larger value, and, therefore, such coatings will last longer.

When choosing an antistatic linoleum, it is necessary to take into account its class. A thicker protective layer corresponds to a larger value, and, therefore, such coatings will last longer.

Do not forget about the color characteristics - in accordance with them, you can choose the material for any style.

It is advisable to pay attention to abrasion and the rate of deformation declared by the manufacturers. In addition, it should fulfill its main role, consisting in the elimination of electric charges. Therefore, you need to choose the product with the highest degree of resistance.

For ordinary offices, it is enough to purchase commercial antistatic linoleum, for rooms with a large number of electrical devices and equipment the ideal option is current-scattering or conductive.

Styling recommendations

Flooring of antistatic coatings is carried out according to the classical scheme. It is necessary to dismantle the old floor finish, carefully level the floor and treat it with a conductive primer solution to ensure good adhesion with glue and the wrong side of linoleum.

A aligned plane is needed not only to eliminate unevenness on the laid linoleum and eliminate the possibility of damage to its lower layer, but also to evenly distribute the voltage.

The base is coated with a thin layer of adhesive, and the butt is laid directly butt-to-butt. It is strongly not recommended to use glue made on the basis of neoprene, since it interacts poorly with the coating, which will lead to a loss of color characteristics.

Current-scattering linoleum sheets suggest the use of a special copper mesh installed to provide grounding, and conductive glue.

The final stage is the elimination of air bubbles with the help of a rubber roller, as well as the joint stitching followed by their sealing by hot welding.

Antistatic linoleum is a unique floor covering designed to protect others from static electricity. And thanks to its impeccable technical parameters, it is deservedly considered one of the most practical and durable.

Scope of application

This type of flooring is designed specifically to eliminate excess static electricity. Conventional linoleum is made from a material that conducts electricity poorly. When a person walks on it, small electric charges may occur that are not harmful to people. And to work with very accurate equipment, such interference is unacceptable. Moreover, these small charges can ignite an explosive or flammable substance.

Antistatic linoleum is used in rooms where high-precision electronics operate, which is sensitive to any effects of electricity.

It attracts less dust and dirt, which is very important in medical institutions.that require constant cleanliness. Thanks to the polyvinyl chloride material that is part of this flooring, this linoleum reduces static electricity. Laboratories, computer centers, server rooms, operating rooms, computer rooms, and MRI rooms are the main places where this coverage is laid.

Recently, it began to be used in residential premises, where many electrical appliances are installed. Appliances like computers, televisions and microwave ovens also produce harmful radiation. When a person comes in contact with a metal device, a weak but noticeable discharge may occur. It not only negatively affects human health, but also badly affects the technique itself and contributes to faster dust accumulation. therefore Antistatic linoleum is recommended for use in any room with a lot of equipment.

Advantages

In addition to the obvious advantages when using this coating in the rooms listed above, antistatic linoleum has other advantages. This material is reliable and safe. It serves for a long time and practically does not undergo mechanical stress, respectively, it is easy to clean and wash. In addition, this coating isolates sound well.

Another undoubted advantage is the fact that antistatic linoleum is resistant to high temperatures. Therefore, it does not constitute a fire hazard.

And its durability can compete with tile and marble. Antistatic linoleum has a high light fastness and can easily withstand temperature extremes.

Thanks to modern technology, at the moment this linoleum can be purchased in any color and design. Moreover, it can be laid on the floor with electric heating. This material is flexible, resistant to wear. It is able to withstand exposure to acid, alkali or oil. The legs of chairs and tables do not leave dents or marks on it.

Stacking procedure

The technology of laying antistatic linoleum has several differences compared with the installation of usually coating. It is important to follow the correct operating procedure, since the manifestation of the protective properties of linoleum depends on this. It is desirable that the installation of this coating was carried out by professional workers.

Before starting work, it is necessary to prepare the floor surface. It should be smooth, and the skew cannot be more than 2 mm per 1 square meter. If necessary, any surface is leveled, dried and degreased, and then treated with a special antibacterial primer. The primer is chosen special, which helps to increase the resistance of the coating to electric current.

You can cut the material only after the linoleum lies in the target room for about a day. This is important for the material to adapt to the temperature and humidity in the room. After a day, the coating is spread out and cut in accordance with the contour and geometry of the room. After that, it can be twisted again on rolls.

When laying antistatic linoleum, conductive glue and strips with the same characteristic must be used. There are self-adhesive strips, but more often they are also laid on glue. These auxiliary elements play an important role, since they create a tap potential. Particular attention should be paid to grounding. It must be consistent with the norms and rules of electrical safety.

Copper tapes should be laid at a distance of 20 cm from each other and from the walls. Laying in strips should be parallel to the joints of linoleum. It is important to connect all grounding elements to each other. In places with special electrostatic sensitivity, conductive tapes are connected to a separate grounding system.

Installation is started when the conductive adhesive has reached the required strength. It is applied with a notched trowel on the back of the linoleum during the unwinding of the roll. It is imperative to carefully align the roll after unwinding it. To get full contact and get rid of air bubbles, use a special skating rink. In case of urgent need, you can make a neat cut in the coating without damaging the copper strips.

Usually, after a day after work, you can already use the room with an antistatic coating.

But the exact waiting time depends on the technical characteristics of the selected type of linoleum.

Care Features

Regular care and cleaning are extremely important for antistatic coating. Excessive accumulation of dust and dirt significantly reduces its electrostatic properties. In no case should polishing, rubbing and various mastics be used when cleaning, as they are good insulators. Because of them, the coating may lose its conductive properties. It is recommended to use degreasing compounds and mastics, able to conduct current.

Popular coatings

Manufacturers of antistatic linoleum offer a variety of coatings. Each of them is intended for its field of application.

For example, commercial homogeneous linoleum widely used in public places where the coating should be as wear-resistant as possible. The thickness of this material is 2 mm. It is durable, resistant to various dents and has good antistatic performance. The presence of a wide range of colors allows you to use it in rooms with a different interior.

In rooms with electronic equipment it can be used antistatic linoleum with a thickness of about 4 mm. Additional thickness is ensured by a special protective layer. There are options for linoleum with a slip-resistant coating. Special moisture resistant coatings are also available. In rooms where it is necessary to provide increased security, lay linoleum with polyurethane reinforcement.

Typically, antistatic linoleum is sold in rolls of 15 or 20 meters. This is enough to cover a room from 60 to 80 square meters. m. When purchasing an antistatic coating, it is necessary to check the availability of quality certificates and the compliance of the material characteristics with the standards.

Antistatic linoleum is a necessary protection tool for rooms where high-precision equipment works. It is thanks to its characteristics that the necessary hygiene indicators, fire safety are provided there and the influence of static electricity on the operation of devices is reduced. But in the living quarters of modern apartments and houses this coating is well established.

The technical characteristics of this type of linoleum make it a worthy competitor to similar materials.

You will learn more about antistatic linoleum from the following video.