Tile adhesive is used for laying ceramics, natural stone, marble or other building materials. All adhesive compositions differ from each other in color, price, resistance to external physical factors. To choose a mixture for laying material, you need to study the best tile adhesives presented in the rating. It was created after evaluating many models, taking into account all the advantages and disadvantages.

Tile glue, which company is better to choose

Practicality, durability, and functionality of building materials depend on the quality of the product. When choosing an adhesive for laying tiles, you must view the rating of the best tile adhesives from well-known manufacturers, which are:

- Knauf - produces a mixture for building materials that does not have an unpleasant odor, which quickly sets on the surface. The brand was founded in 1932, it supplies products to many countries.

- Ceresit - The company was founded in 1906, annually produces new paints, adhesives and other means for building materials. Branches of the company are present in many countries of Europe and America.

- Mapei - produces high-quality tools for laying building materials since 1937. The company worked as a small family business, then grew into a single recognizable brand.

- Weber - manufacturer of dry mixes for construction and repair. It has been on the market for more than 100 years, it supplies goods to 57 countries, the product is manufactured in 200 factories.

- Sopro - produces goods for construction work, which consist of light, adhesive materials, they are designed for tiles or ceramics. The company supplies construction chemicals to many countries in Europe.

- Bergauf - The distributor produces high-quality mixes for construction work; it has been introduced to the market since 2005. The tool is affordable, it is chosen not only in Europe, but also in many countries of Russia.

- Glims - produces goods for laying tiles since 1994. The product is of high quality, instantly dries, guarantees adhesion to any surface. It is spent economically, has no unpleasant smell.

- Litokol - manufactures products since 1968, using only high-quality, safe means. It is supplied to many European countries and guarantees maximum adhesion to ceramics.

- Unis - The company was established in 1998, produces building and finishing materials for ceramics or tiles. They do not have a pungent odor, adhere to the surface, and do not cause allergies when working with it.

Tile Adhesive Rating

Tile adhesives have different composition, quality, solidification speed and other nuances. Before forming the rating, comparative tests were carried out, which gave an idea of which tile adhesives can be considered the best. Together with the tests, the opinions of buyers and experts, which were no different from the test results, were taken into account. Additional characteristics:

- Frost resistance

- Grouting

- Open hours

- Proportions for mixing,

- Tile sliding

- Price,

- Volume.

After receiving all the data, a rating of the funds that can be used during construction and tile laying was formed.

Types of tile adhesive

In accordance with GOST R 56387-2015 “Dry adhesive building mixtures on cement binder” and standard EN 12004: 2007, three types of adhesive compositions are sold on the Russian market:

- Cement-containing.

- Dispersion.

- Reactive.

To the first group the most affordable mixes based on a mineral binder - gray or white cement.

In the composition also:

- fillers (quartz sand, bone meal, etc.),

- modifying, elasticizing and other additives that increase the density of the composition, frost resistance, viscosity, ductility and other qualitative characteristics of the products,

The material is sold in the form of dry powder, packaged in paper bags, plastic buckets. Suitable for working with any kind of cladding:

- standard tile, clinker, terracotta and others,

- ceramic granite,

- artificial and natural stone,

- mosaic made of glass, ceramics, etc.

When mixed with water, a rather thick paste forms with a considerable shelf life of up to 3 hours. The mass is applied with a spatula, while the flow rate and thickness of the layer depend on the characteristics of the base, decorative coating, laying conditions. Frost-resistant, moisture-resistant products, as well as compositions compatible with floor heating systems, are produced in separate series.

Dispersive adhesive for tiles in the bathroom is considered one of the safest in the work.

Its base is a methyl methacrylate binder, supplemented with an inert filler and various additives. Products are packaged in plastic containers and buckets in the form of a ready-to-use one-component paste. The material is flexible and has good adhesion, so it is recommended to use it for mounting coatings on deformable or non-absorbable substrates.

Acrylic adhesive is waterproof, but at the same time vulnerable to acids, alkalis, low temperatures. They can only be used indoors where the use of aggressive detergents or disinfectants is not intended.

Reactive compositions are a professional multicomponent series.

Polyurethane, epoxy or polyurethane-epoxy thermosetting resins are used as a binder. To prepare the glue, it is necessary to introduce a catalytic additive, a hardener or 1-3 activators. You need to breed the base correctly, otherwise the composition will dry for a very long time.

If you follow the instructions, the open time of the paste does not exceed 30-50 minutes, respectively, you must work with the mixture quickly, but carefully. The instructions for such formulations contain, as a rule, a warning: the products are poisonous, can cause irritation, poisoning and various allergic reactions.

Ready-made mixtures are non-shrinking, water-, frost- and acid-resistant, highly elastic. In fact, it is a very good material for working on all types of substrates, including metal, aerated concrete, etc. Suitable for working with any kind of stone slabs, regardless of their dimensions and other characteristics.

Surprisingly, but for gluing tiles, you can use another type of mounting mixture - “liquid Nails". These polymer compositions have good adhesion, high initial setting strength, and are elastic. Therefore, they can be used for any kind of substrates. One “but” - the tube, as a rule, contains a small amount of glue, respectively, this method of fixing the linings can not be called economical and cheap. We recommend using liquid nails to pinpoint individual tiles or on an area of not more than 2 m².

But we recommend that you never use another express method for gluing ceramic cladding. Some "masters" offer fallen off cladding elements to fix with a household glue gun. The method is undoubtedly simple, but very unreliable. Tile is a heavy material and a standard rod adhesive simply cannot withstand its weight. Specialized adhesive mixtures or special mounting compounds of ultra-strong fixation "liquid nails" are required.

Labeling Features

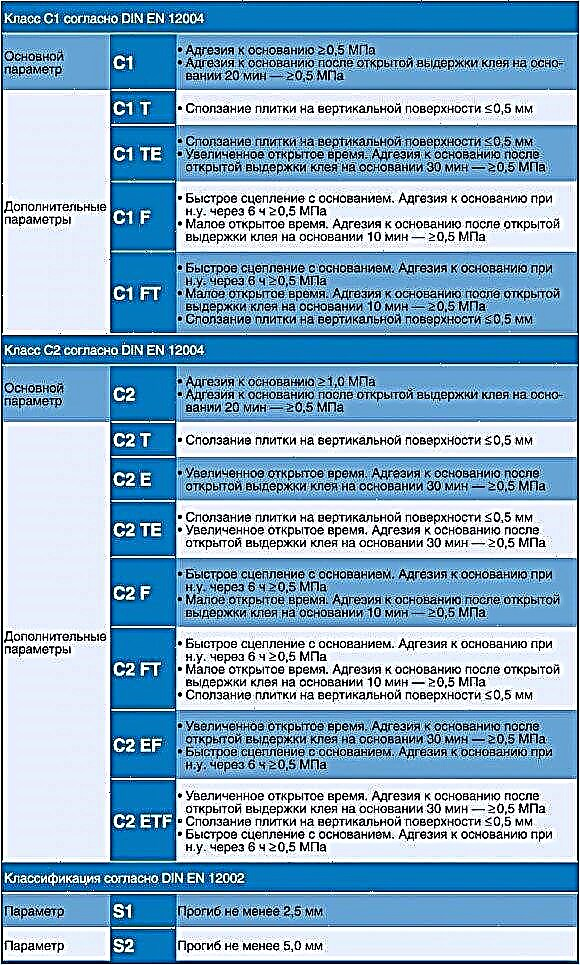

Regulatory documents (GOST R 56387-2015, EN 12004: 2007) recorded a number of standard markings that allow to determine the main characteristics of the product. In particular:

- C - cement binder mixes.

- D - dispersive tile adhesive.

- R is the adhesive composition of the reactive type.

In practice, almost all letters are supplemented by the numbers 1 and 2, which means “basic” and “reinforced”. That is, D1 is a standard dispersion adhesive for indoor and outdoor use, and D2 is its improved version. The same is true for polymer formulations.

Consider marking with cement adhesives as an example.The standard EN 12004: 2007 approved a number of qualifying designations (classes):

- С0 - products for the installation of tile materials with a water absorption level of up to 5% by weight. Scope - indoors.

- C1 - adhesive for ceramic tiles and porcelain stoneware, used for indoor and outdoor use.

- C2 - adhesive composition, which is subject to increased requirements for a number of qualitative characteristics.

- F - mixtures with a short pot life (quick hardening).

- T - a solution of increased thixotropy. That is, due to the introduction of special additives into the composition, it perfectly holds the tile on vertical and inclined surfaces, preventing it from slipping during gluing.

- E - mixtures with prolonged pot life (open layer).

- S1 - adhesives from a series of elastic, which after hardening give a deflection of up to 2.5 mm.

- S2 is a highly flexible compound designed for highly deformable substrates. The deflection limit is up to 5 mm.

Thus, even the most complex markings are decrypted quite simply. For example, the name “Kerabond C2ES2” means that you have a cement reinforced adhesive with a prolonged open layer and a high degree of deformability.

In addition to special marking, a standard one is also used. On the packaging you can find such pictograms as the thickness of the mixture, flow rate, time to go, operating temperature and others. They, as a rule, are as simple and clear as possible even without explanation.

Rating of the best tile adhesives

| Category | A place | Name | Rating | Price |

|---|---|---|---|---|

| The best universal adhesives for tiles and porcelain tiles | 1 | Litokol Litoflex K80 | 9.8 / 10 | 530 |

| 2 | Ceresit CM 14 Extra | 9.6 / 10 | 420 | |

| 3 | Weber easy fix | 9.1 / 10 | 280 | |

| The best frost-resistant tile adhesives | 1 | Ceresit CM 17 Super Flex | 9.9 / 10 | 1 200 |

| 2 | KNAUF Marble | 9.7 / 10 | 510 | |

| 3 | Unis XXI | 9.1 / 10 | 200 | |

| The best thick layer tile adhesives | 1 | Mapei Keraflex Maxi | 9.7 / 10 | 1 260 |

| 2 | Litokol Litofloor K66 | 9.6 / 10 | 460 | |

| 3 | Ivsil maxi plus | 9.2 / 10 | 215 | |

| The best reinforced tile adhesives | 1 | KNAUF Flizen Plus | 9.6 / 10 | 315 |

| 2 | Unis Granite | 9.5 / 10 | 355 | |

| 3 | KIILTO PRO FIX | 9.4 / 10 | 450 |

Litokol Litoflex K80

Having crossed the fiftieth anniversary, the Italian company can rightfully be called one of the world's leading manufacturers of dry mixes for construction. Since 2002, the company has its own production in Russia, for which it has a separate plus - both for jobs and at an affordable price with high quality, which is ensured by the localization of production.

Specifically, the Litoflex K80 mixture is a full-fledged “universal”, suitable for both indoor and outdoor work. High adhesion, moisture and frost resistance - all this is present to the proper extent. This cement-based mixture with synthetic additives is specially designed to work when installing underfloor heating and, which allows it to be recommended for inexperienced tilers, has an increased correction time - up to an hour at normal temperature. That is, you can not be afraid that the tile has time to “stand up” on the adhesive layer crookedly - you will always have time to fix it. Of course, the time for complete grasping due to this is decent, but we don’t have the deadlines, is it logical?

Naturally, when choosing glue, it is worth reading the table of applicability for tile size and type of base. This applies to any glue - but, as you can see, with the Litoflex K80, the pluses there are set pretty well.

- Excellent adhesion

- Moisture and frost resistance

- Decent elasticity

- Long correction time

- Slow final hardening

Ceresit CM 14 Extra

Do not trust Italians? Well, then Ceresit is your choice: the old German company, which began work at the end of the 19th century, will not let you down. Like Litokol, the company has its own production facilities in Russia (and even larger in scale - the sixth plant has already been commissioned), therefore it provides very pleasant prices for its products.

Glue CM 14 Extra - highly adhesive, suitable for facade work, installation of tiles in wet rooms, work with underfloor heating and over moisture insulation. The proprietary “chip” is the introduction of reinforcing microfibers, as the company calls them, to increase the strength of the glue and give it increased impact resistance: this is just for floor tiles and porcelain. However, it should be recommended to an experienced person: the correction time is three times less than that of the Litoflex K80.

Since the performance characteristics of both adhesives are very high (and we especially note the excellent frost resistance - they will not work except for Oymyakon), we will put CM 14 Extra tile adhesive in second place in the rating, despite the lower price: still work with Litokol more convenient, and for this you can overpay the extra hundred rubles per package.

- Good impact resistance

- Suitability for facade work in cold climates (minimum operating temperature - minus 50 degrees)

- High adhesion

- Limited correction time

Weber easy fix

Low-cost tile glue from Vetonit is best suited for budget repairs. Budgetary, not only because of the price of glue, but also because of its incompatibility with underfloor heating. If you want to “insulate your feet” - choose Ceresit or Litokol, well, and if a warm floor is not planned, then the glue can be taken “easier”.

We’ll add “undemanding” to the attributes of the proposed repair: the fact is that the correction time for this glue is short, only 15 minutes. Do not have time to fix it - well, you have to come to terms. But quick setting has a plus: faster, the room will come into a “suitable” state - and often repairs are carried out in the apartment where they already live, and the possibility of a quick “commissioning” of a bath or toilet will certainly not be superfluous. Paul, for example, will get up in 36 hours.

We note good moisture resistance of the glue and good antiseptic properties: in general, it costs its money unequivocally.

- Low price

- High performance

- Short correction time

- Incompatibility with underfloor heating

Ceresit CM 17 Super Flex

In principle, the majority of Ceresites have good low-temperature properties, but it is precisely this tile adhesive that is recommended for working under conditions of constant freezing cycles. It has excellent strength characteristics in such conditions - at least 1.4 MPa adhesion according to the technical description, high elasticity. This will allow you to confidently work with heavy tiles, working "on the street", where it will water it, but freeze the night cold. The only exception is marble laying; you cannot use CM 17 Super Flex for this.

The tiler will have about half an hour to correct under normal conditions, which can be recognized as quite normal time. The glue has high adhesion and resistance to creep, so for vertical surfaces it is “what the doctor prescribed”.

- High elasticity

- Resistance to multiple freezing cycles

- Pretty high price

- Not applicable for marble tile

KNAUF Marble

Knauf does not need to be represented: founded by two mining engineers in the early thirties, the German company quickly rose not only as a manufacturer, but also as a developer. The first production of gypsum plasterboard, machine plaster - for this it is worth saying “thanks” to Alfons and Karl Knaufam.

In our country, the company has been known since Soviet times (cooperation began in the seventies, although after the war the company was on the "bourgeois" side of divided Germany), and since 1991 it has completely developed: its own production facilities, a training center. However, let's move on to a specific brand of tile adhesive - and it was not in vain that it got into our rating.

At a time when most manufacturers guarantee the preservation of strength characteristics during 50 freezing cycles, Knauf boldly steps forward: 75 cycles with a lower operating level of -50 degrees are indicated for Marble. The glue works perfectly in conditions of strong daily temperature drops, but in adhesion it is almost one and a half times inferior to Ceresite - 1 MPa instead of 1.4. In addition, he has a short correction time - only 10 minutes, so we recommend it first of all with a full hand. Choose for yourself - to invest in the more expensive “Ceresit”, or you can try to save money by choosing “Knauf”.

- Good adhesion

- Excellent frost resistance

- Affordable price

- Low correction time

Unis XXI

Domestic tile glue is inexpensive, but it can withstand its 50 freezing cycles laid down in accordance with GOST. But it is worth warning right away: you should not buy it for laying heavy and dimensional tiles, especially on vertical walls, its “element” is a work of a smaller scale, starting with mosaic ones.

Also, the adhesive is demanding on the base - it must be undeformable and properly aligned. The correction time is short: up to 15 minutes. If you are confident in your abilities and are not going to demand the impossible from the glue, then it will allow you to save some money, but its features still need to be considered when choosing: do not make a mistake.

- Decent frost resistance

- Good adhesion

- Short correction time

- Application restrictions

Mapei Keraflex Maxi

Mapei is nothing more than an abbreviation for Materiali Autarchici Per Edilizia e Industria, so it’s easy to understand that the company is based in Italy. Moreover, for a reason that is now well known to us - since an embargo was imposed on Italy during the time of the unforgettable Duce, local manufacturers had to urgently deal with import substitution. "Autarky!" - proclaimed Mussolini, and Rodolfo Squins said: "It will be done." In our country, the company has been operating since 2002, starting with a small factory in Moscow, and soon opening two full-scale production facilities.

If you are going to work on an uneven surface, then to achieve a high-quality and durable result you will need a special thick-layer adhesive. Keraflex Maxi is just one of them - it works with a layer thickness of up to 15 mm, but much more? Slip-resistant and flexible tile adhesive is equally suitable for indoor and outdoor use, gives an average of 45 minutes to correct laying, is compatible with most materials except marble. At the same time, it provides good adhesion even after immersion in water - 1.1 MPa, which is larger than that of many adhesives and "dry", and in normal humidity gives as much as 2.6 MPa. Therefore, it is especially worth recommending for laying heavy tiles indoors, on walls and floors: it will be kept in good conscience. But for the street it is worth advising it only for a moderate and warm climate: the minimum operating threshold is minus 30 degrees.

- Excellent adhesion

- Performance in a layer up to 15 mm

- Elasticity and impact resistance

- Not recommended for use with materials that are sensitive to sunburn and capable of changing color.

Litokol Litofloor K66

The adhesion of the glue is worth noting, lower than that of Keraflex Maxi, and decently lower - only 1 MPa. Therefore, under severe conditions (high "passability" of the room, additional mechanical stresses), it is still preferable to have a thick-layer adhesive from Mapei. For an ordinary apartment, the capabilities of the Litofloor K66 are fine. The glue is undemanding to the accuracy of laying, it gives up to 35 minutes for correction. So in general, we can definitely recommend it.

- Performance in a layer up to 25 mm

- Excellent elasticity

- Good low temperature properties

- For "home" use, they are practically absent, except for a long time of full cure (14 days)

Ivsil maxi plus

The Moscow company is incomparable in scale with the European “grandees” of the transnational level, and it is more difficult to find its products on sale - but it compensates for this with a low price and good quality (especially considering the price). Maxi Plus tile adhesive works in layers up to 20 mm thick, and this is a very worthy indicator. Add to this good frost resistance and compatibility with underfloor heating.

But there are also disadvantages - where without them? The adhesion of this glue against the background of even comparable in price is not the most impressive - only 0.8 MPa. This should be taken into account clearly when buying. There will be little time for correction - only 15 minutes. In general, intending to save money, do not lose: the glue is available, but also specific.

- Low price

- Work in a layer up to 20 mm thick

- Short correction time

- Poor adhesion

KNAUF Flizen Plus

Inexpensive tile glue is quite “quick”, so you need to lay the tile with your full hand: the correction time is only about 10 minutes. The glue has excellent frost resistance (75 cycles, the minimum operating temperature is minus 50 degrees), sufficient elasticity, but due to not the greatest adhesion (0.8 MPa), it should be used primarily for unloaded linings. Here it will be just right - the benefit can be used with tiles up to 60x60 cm in size and specific gravity up to 60 kg / m2.

Note that the adhesive is applicable only on non-deformable substrates and works with a layer thickness of up to 6 mm: do not neglect the alignment.

- The ability to "hold" in the vertical dimensional and heavy tiles

- High frost resistance

- Limited adhesion

- Short correction time

Unis Granite

Yunis is traditionally pleased with the price - well, if you really need glue for massive and dimensional tiles with a specific gravity of up to 60 kg / m², then Granite glue corresponds to this need in the company's lineup.

The adhesion to concrete (for this material it is indicated in the characteristics of all adhesives) is very decent: 1.5 MPa, but it does not fit well on the screed - therefore, we will classify it as “purely facade”. Fortunately, the frost resistance class is already F100. The surface must be well-aligned, deviations are allowed by the manufacturer no more than 1 mm per meter length. It’s necessary to tinker, but the result will be good. What kind of price is especially nice, isn't it?

- High adhesion

- Excellent frost resistance

- Affordable price

- Demanding for surface preparation

KIILTO PRO FIX

Italy, Germany ... Let's not forget about Finland: the Kiilto Oy company, which celebrated its centenary this year, is also worthy of getting into our rating - the benefit and conditions in Finland are very similar to ours, so tile adhesive is good for them in Russia in most regions will feel at home.

First of all, we note excellent adhesion: 1.5 MPa, almost twice as high as that of Knauf. It is a pity that the class of frost resistance of Finnish glue unexpectedly turned out to be lower - F35, not F50. According to applicability, the adhesive is universal, it works in a layer up to 6 millimeters thick. In conditions of high humidity, it is necessary to apply waterproofing before laying the tiles and hydrophobic grout - after, the manufacturer directly indicates this.

- High adhesion

- Good frost resistance

- Short correction time

Which tile adhesive to choose?

Although in general modern tile adhesives are quite versatile, there are points to consider. Already in central Russia from the glue used for facade work or in unheated rooms, high frost resistance will be required. Its class must be at least F50 - that is, the glue will be guaranteed to maintain its characteristics for 50 freezing cycles. Naturally, pay attention to the lower temperature limit of operation: for example, for many adhesives it is only -30 ° C, and not enough for a cold climate. You will see glue in the store, operated up to minus fifty and with the class F75-F100 - this will be a good choice.

For dimensional and heavy tiles, especially laid on vertical surfaces, you need your own glue - they are usually called “reinforced”, buying a “station wagon” designed to work with compact and lightweight tiles will not be the best choice for durability. In the bathroom, shower, especially in the pool, glue is primarily required for moisture resistance: check in the characteristics what adhesion the adhesive provides if it gets wet.

By the way, about adhesion: it is indicated as the pressure required to tear off the tile from a layer of fully cured adhesive. For example, for an adhesive with an adhesion of 1.5 MPa, tearing off a tile will be one and a half times more difficult than for an adhesive with an adhesion of 1 MPa. But note that this characteristic is indicated for averaged "standard" conditions when laying on concrete, for other materials it can seriously differ.

Rules for choosing glue for the bathroom

Compositions for fixing tiles and porcelain tiles are classified:

- By field of use: for internal work, universal, suitable for indoor and outdoor use. Some manufacturers have frost-resistant series.

- In appearance and size of the cladding used. Separately, groups of adhesives for ceramic or glass / metal tiles, porcelain stoneware, mosaics, natural stone, unglazed cladding, monocotture, clinker, etc. are produced separately.

- By the type of base: for mineral (cement and anhydride screeds, gypsum plasters, aerated concrete walls, etc.), for organic (chipboard, OSB). Separately, mixtures for typical, complex and deformable surfaces are produced.

- According to operating conditions: standard, for rooms with a high level of humidity (bathtubs, showers, pools, tanks), for underfloor heating, stoves.

Based on the foregoing, it is possible to determine the following criteria for the selection of adhesive compositions for tile facings:

Application area

The average temperature indoors or outdoors, humidity, the intensity of the interaction of water, vibration, dynamic loads - all this seriously affects the strength of fixation of the material. Simple logic suggests that, for example, for laying tiles on the porch, it is better to purchase a frost-resistant mixture for heavy facings. And for finishing a shower room with GCR walls, a highly elastic hydrophobic glue with antifungal additives is needed.

When lining the floor in the bathroom, three more important factors must be considered:

- Operation class. For areas of the most intensive use (public baths, washing, garages, etc.), mixtures of professional series with high resistance to vibration and mechanical stress, chemicals, etc. are recommended. And for baths in the house, apartment, universal universal glue for tiles and porcelain is enough .

- System availability floor heating. Simple mixtures do not withstand the intense temperature difference, crack over time, exfoliate. Therefore, elastic adhesives with the mark “heat-resistant” or “for warm floors” are needed.

- Water interaction. If the shower does not have a pallet (acrylic, metal, stone), and there is no waterproofing under the lining, then it is necessary to use not waterproof, but waterproof adhesives. Or, at the stage of solution preparation, introduce a water repellent into the mixture in the form of a liquid (Tiprom 80, Tegosivin HE 328) or dry powder (Penetron Admix, Idrosilex). Such a layer will not allow water to leak into the base (screed, floor slab, etc.) and will prevent its damage, mold, peeling of the lining, etc.

Tile type

Tiles and porcelain tiles - these are different in size, density and weight of the finishing materials. The first is lighter and less durable, so base mixes are used for installation. Porcelain and stone tiles require reinforced mixtures with good adhesion and elasticity.

To finish the floor, walls, bowl of the bathroom or the pool with mosaics, you need a special glue made on the basis of white cement. It does not shine through transparent glass, and does not give an ugly grayish tint to color.

One can not help but remember about natural facings. The bathroom, trimmed with tiles of onyx, malachite, granite, looks expensive, luxurious. But there are capricious materials in this series. Marble, slate and the like are characterized by high porosity, have the property of “pulling” pigments. To work with them, manufacturers strongly recommend the use of white adhesives. Otherwise, stains, stains may form on the surface from the usual cement composition.

In addition to size and material, you must also take into account the degree of absorption of the tile. Classic tile and porcelain stoneware has a water absorption rate of up to 5% by weight. But products made of glass, metal and the like have zero absorption coefficient of the liquid. Therefore, for their fixation on the floor and walls, reinforced dispersion or multicomponent reactive compositions are used.

Base

Standard compositions are recommended for work on strong, not crumbling plastered walls, matured floor screeds. For wall cladding, it is better to choose thixotropic, quick-hardening mixtures.

If the walls of the bathroom are made of foam or gas blocks, lined with drywall, glass-magnesite sheet, and the floor is a painted plank or plywood flooring, then it is best to work on them with super-elastic adhesives. They withstand a high degree of vibration, as well as a variety of dynamic loads without compromising their integrity.

Highly adhesive and polymer adhesives are useful for working on the old tiles, waterproofing layer, the base of metal, rubber, PVC. Although many manufacturers claim that basic and universal adhesives can work on existing tiles. For a firm grip, you must first:

- Remove glaze with sandpaper, wire brush or drill with brush head.

- Primer with quartz sand like Concrete Contact.

Glue parameters

Paradoxical as it may seem, but first of all you need to pay attention to the specifics of adhesives. Professional series are more “strong”, with a prolonged lifespan, in some cases even toxic. Designed to work on large areas and in difficult conditions. Inexperienced masters, he is not "on the shoulder."

Household compositions differ in their simple composition, averaged indicators for thixotropy, vitality, workability, etc. Not only professionals, but also beginners can work with them, therefore they are most often used for independent decoration of bathrooms in private houses, apartments.

Among the characteristics of the adhesive, special attention is paid to adhesion (adhesion strength). The heavier and more dimensional the lining, the higher this indicator should be. The standard level for ceramic tiles, which provides tight fixation taking into account vibrations and loads, is from 0.5 MPa and above. Simply put, a layer of glue should provide a minimum tear resistance of 5 kg / cm². For heavier and larger porcelain stoneware, the adhesion index should be higher - about 0.8-1 MPa.

Note that this also has the flip side of the coin. When laying ordinary tiles in the bathroom, do not use superstrong compositions for heavy facings. They “hold”, of course, better, but such a powerful glue in the curing process can break the lighter finishing material.

When choosing a composition for facing walls, columns and other vertical or inclined surfaces, such a characteristic as the thixotropy of the composition plays an important role. It affects the sliding resistance of the tile cladding. The larger and heavier the finish, the higher this indicator should be. In accordance with the marking system, the name of the adhesive must contain T1 or T2.

Another important factor is the thickness of the coating. Issued:

- thin layer mixtures. They are applied with a layer of up to 5 mm and are designed specifically for fixing on well prepared rough substrates. As a rule, they are used for wall decoration in bathrooms, kitchens, hallways, showers, etc.

- Thick-layer mixtures with a permissible thickness of up to 25 mm. With their help, you can simultaneously glue the tile and partially align the base, that is, fill small cracks, small pits. Often used for flooring.

Climatic conditions

Three factors must be taken into account simultaneously: humidity level, interaction with liquids and thermal factor. Do not use the same glue for facing the kitchen, outdoor pool and stove. In the first case, a fairly simple, basic composition. In the second - special hydrophobic mixtures with frost-resistant additives. And for the third - heat-resistant compositions marked "for stoves" or "for underfloor heating."

Thus, in each case, you need to choose the most suitable adhesive according to the conditions.

MAPEI S.p.A.

Price: from 500 rubles / unitary enterprise.

The MAPEI® group of companies has 80 years of experience and more than 70 plants in 32 countries. The concern specializes in the production of construction chemicals for professional and household use. The line of adhesive compositions for ceramics is one of the most extensive and has more than 50 types. In assortment:

- Basic compositions for tiles and medium-sized porcelain tiles (Kerabond, Mapeklej).

- Improved adhesives for working on complex surfaces, as well as for places with intense loads (Keraflex, Kerafloor).

- Highly deformable compositions for ceramic and natural heavy tiles made of granite, slate, etc. (Elastorapid, Mapestone).

- Frost-resistant universal mixes (Kerabond T-R, Ultralite S).

- White compositions for vertical and horizontal surfaces (including complex ones) used for glass, ceramic and marble mosaics (Adesilex, Tixobond).

- Dispersion and reactive adhesives for highly deformable substrates and capricious types of cladding (Adesilex P22, Keralastic).

In order to impart special properties to glue (to increase thixotropy, elasticity, etc.), the manufacturer offers various improving additives, such as Isolastic, Keracrete, etc. In general, the line of adhesive mixtures can be called rich, because it is easy to select glue practically in Mapey’s products under any conditions of use.

Litokol

Price: from 430 rubles / unitary enterprise.

For almost 50 years, the Italian company has been supplying construction products under the Litokol® brand to 40 countries of the world. The Russian plant in Noginsk produces for the domestic market almost the entire range of adhesive materials available. In the nomenclature of more than 25 types of various adhesive compositions for stone cladding:

- Universal mixes for ceramics, porcelain stoneware, terracotta, clinker, marble, mosaic products (Litokol X11, Litokol K17).

- Reinforced flooring compositions (Litofloor K66, Litoplus K55).

- Improved highly deformable compounds suitable for floor heating systems (Litoflex K80, Hyperflex K100).

- Special white mixes for glass and stone mosaics with painted surfaces (Litoflex K80 White, Hyperflex K100 White).

- Super-elastic frost-resistant compounds for facade work (Litoflex K81, Litostone K98).

- Dust-free weather-resistant adhesives (Litoflex K80 ECO).

- Polymer-containing deformative adhesive pastes for indoor and outdoor use (Litoacril Plus, Litoelastic).

Clay Litokol is released, as they say, "for all occasions" and receive only positive feedback from customers. But, unfortunately, this brand, like other well-known brands, sometimes has fakes.

One cannot but mention several important points. The plant introduced multistage quality control of products, and a safety check is carried out not only at the state level, but also by its own laboratory. The company pays special attention to the training and certification of specialists working with brand products. A training center has been opened at the plant, functioning both in standard mode and remotely. Reference books, calculators, video tutorials and other educational materials are available to everyone.

Weber saint-gobain

Price: from 320 rubles / unitary enterprise.

Saint-Gobain Corporation is one of the largest industrial producers in the world (according to Forbes rating) with vast experience and representative offices in 67 countries on 5 continents. The group of companies operates in various industries, including construction. Three plants for the production of dry mixes have been opened in Russia. Weber-Vetonit® products are recognizable, and according to the number of certificates they correspond to the slogan of We care (Care is our work).

The range of adhesive cement compositions for tiles includes:

- Standard compositions for exterior and interior use with antifungal, hydrophobic and plasticizing additives (Weber.Vetonit Optima, Weber.Vetonit Easy Fix).

- Universal adhesives from the dust-free series for working with tiles, porcelain stoneware, mosaics and natural stone (Weber.Vetonit Profi Plus, Weber.Vetonit Stone Fix).

- Improved mixtures are highly elastic, frost and weather resistant, easy to use (Weber.Vetonit Ultra Fix, Weber.Vetonit Mramor).

In the product range of Weber-Vetonit there are practically no polymer-containing adhesives. According to customer reviews, this is one of the best brands for domestic purposes.

We also note that, in addition to high quality and compliance with the declared characteristics, the products of the plants undergo mandatory and voluntary safety certification. In particular, the company has the right to label products with the Ecomaterial mark.

Henkel-ceresit

Price: from 300 rubles / unitary enterprise.

Since 1990, HENKEL Bautechnik GmbH has owned two fairly well-known brands of construction products: Ceresit® and Thomsit®. The range includes a complete set of industrial mixtures for the construction and decoration of buildings. For tile facings, the concern's plants produce:

- Basic fixing solutions (Ceresit CM 9, Ceresit CM 11 Plus).

- Elastic compounds for deformable subfloors and underfloor heating (Ceresit CM 14 Extra, Ceresit CM 17).

- A special series of adhesives for large-format tiles, as well as for glass, marble mosaics, facade finishing works (Ceresit CM 12, Ceresit CM 117).

Despite the modest, in comparison with other brands, assortment, Cerezit has a good choice of adhesives for household and office use. The emphasis is on the size and type of tile material. In addition, almost all products contain frost-resistant and anti-mold additives, so it can be successfully used for both interior and exterior decoration.

We also note that each type of glue passes mandatory certification for safety and compliance with Russian standards. According to numerous buyers and craftsmen, Ceresit products are one of the best among budget brands.

Knauf

Price: from 300 rubles / unitary enterprise.

The KNAUF group of companies has been developing the construction industry for over 80 years. The main emphasis is on dry work, so the range includes the same finishing materials under the brand of the same name. As a base material, gypsum is used almost everywhere, less often - cement. Tile adhesives are made on the basis of white and gray cement binder. The product line is limited to 6 types:

- KNAUF Fliesen - basic composition for interior work with standard size tiles. Designed for facing smooth, non-deformable substrates (without heating).

- · KNAUF Fliesen Max - an improved version of the previous glue with the ability to apply a layer of more than 20 mm.

- KNAUF Fliesen Plus is a reinforced compound with frost-resistant additives for large-format cladding, placed inside and outside the building.

- KNAUF Schnell is a quick-setting weatherproof adhesive.

- KNAUF Mramor is a white adhesive for glass mosaics, marble, slate and other tiles with high requirements for fixing compositions.

- KNAUF Flex is a highly elastic mixture with reinforcing additives, working equally well on horizontal and vertical bases. It is used for finishing baths, showers, facades, socles, stairs, etc.

Knauf products - this series is not for complex tasks, namely for the home or office sphere. Despite the modest choice, the adhesives of this brand are of good quality, have proper certification.

WOLMA

Price: from 270 rubles / unitary enterprise.

Volgograd gypsum plant was established in 1943. The manufacturing enterprise gradually increased its turnover, encompassed new areas, which allowed it to stay afloat in the difficult 90s. In 2006, the VOLMA® trademark was registered. Today, under this brand, a wide range of various products for the construction, decoration and reconstruction of buildings is produced. The range of tile adhesives is classic. Includes:

- Base mixes for thin and thick-layer application (VOLMA-Interior, VOLMA-Ceramics).

- Compositions with increased adhesion force for large-format and heavy coatings (VOLMA 1 MPa, VOLMA-Multikley).

- Moisture- and frost-resistant compositions (VOLMA-Ceramic plus).

- Products for underfloor heating systems (VOLMA-Teplit).

The entire line of tile adhesives is available in accordance with GOST 31357-2007. According to buyers, the plant’s products are not bad, inexpensive, and meet the declared characteristics.

Ivsil

Price: from 240 rubles / unitary enterprise.

IVSIL can be described in several terms - young, successful and dynamically developing.In 1997, a small plant for the production of sand-cement mixtures was organized in the Moscow Region, which gradually grew into a huge industrial complex. Products under the own registered trademark IVSIL® are supplied throughout Russia and the CIS countries. Since 2000, the company's product line has expanded with a series of tile adhesives. Today Ivesil offers:

- The base mixtures are thin and thick for working inside and outside buildings. There are both domestic and professional types (IVSIL FIX, IVSIL START).

- Superstrong compositions for heavy linings, fixed both on vertical and horizontal bases (IVSIL CLASSIC, IVSIL GRANIT).

- Quick-hardening adhesives for work in wet and dry rooms (IVSIL EXPRESS +, IVSIL OPTIMA +).

- White compositions for capricious types of finishing coatings, such as marble, glass (IVSIL MOSAIK).

- Waterproof mixes for work in pools, showers (IVSIL AQUA).

- Heat-resistant compounds designed for stoves, fireplaces, floor heating systems (IVSIL TERMIX).

Ivsil products are certified for compliance not only with Russian but also with European standards. The masters also have it in good standing, which is confirmed by positive reviews.

GLIMS

Price: from 220 rubles / unitary enterprise.

Podolsk JSC GLIMS-Production was established in 1995 on the basis of an old agricultural enterprise for the repair of various equipment. The founders set a goal - to distribute in the domestic market a full range of modern materials for the construction, repair and restoration of buildings. One of the promising areas are assembly adhesion mixtures:

- Basic for working with interior decoration materials (GLIMS G-11, GLIMS G-21).

- Improved for internal and external use (GLIMS GreyFix, GLIMS StrongFix).

- Reinforced for ceramic and natural cladding (GLIMS RealFix)

- White tiles for special types of tiles (GLIMS WhiteFix, GLIMS HiFix)

To increase the hydrophobicity of the solution, its ductility, resistance to vibration and deforming loads, the manufacturer offers a modifying additive GLIMS PRO LatexFix. With its help, a composition with polymer characteristics can be made from ordinary cement glue.

According to customers, the Glims series of tile adhesive mixes is easy to work with, and white can be used for fixing and grouting.

BOLARS

Price: from 200 rubles / unitary enterprise.

Bolars is a relative newcomer to the building materials market. 15 years of experience, a wide dealer network has made the brand recognizable, and products - in demand among the masters. The range of tile adhesives includes 9 varieties. Including:

- Classical mixes for internal and external finishing work (BOLARS Basic, BOLARS Standard).

- Quick-hardening for express repair (BOLARS Express).

- Improved mixes for vertical and horizontal use (BOLARS Object, BOLARS Plus).

- · Atmospheric and waterproof adhesives (BOLARS Elastit, BOLARS Aqua Plus).

- Compositions for large-format tiles and natural cladding (BOLARS Elite, BOLARS Granite).

All products of this brand are certified. Negative feedback from customers about the adhesive mixtures Bolars almost never occurs.

Miners

Price: from 200 rubles / unitary enterprise.

The Moscow mine factory "Prospectors" on the market not very long ago - since 1992. But it is already known throughout Russia as a manufacturer of budget-friendly and good-quality products. The group of cement tile adhesives presents all the most necessary types:

- The standard is for the installation of ceramic and porcelain stoneware in dry and wet rooms.

- Premium - reinforced composition for bulky plates.

- Plus - a weatherproof mixture with a high degree of plasticity. It is combined with any floor heating systems, including electric.

- Luxury - products for pools, fountains and other similar facilities.

- Quick - composition for urgent tiled work indoors.

The plant does not produce polymer adhesives.But cement can boast of quality in accordance with Russian standards (TU 5745-017-11779802-2003). The buyer's complaints are caused only by the packaging, but not by the composition itself.

In conclusion, we note that our estimates consisted of many factors, such as assortment, information support, packaging quality, customer reviews and many others. We hope our rating will help you determine and achieve the desired result.

Advice! If you need a master to repair the bathroom, there is a very convenient service for the selection of specialists from PROFI.RU. Just fill out the details of the order, the wizard will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work that will help with the choice. It looks like a mini tender. Placing an application is FREE and does not oblige you to anything. It works in almost all cities of Russia.

If you are a master, then follow this link, register in the system and be able to accept orders.

Types of glue and their application

Choose tile adhesive for the floor, depending on the base and size / type of tile. The larger and heavier the coating, the greater the strength the adhesive should have. Everything is more or less simple here. The description indicates with what materials and sizes this composition can be used. With the grounds a little more complicated. It is necessary to look at the type, stability, strength, whether it is afraid or not of moisture. In general, to choose, you need to know the types of tile glue. According to the type of binder, they are of three types: cement, dispersion and acrylic two-component.

Types and classification of tile adhesive

Types and classification of tile adhesive

Cement based adhesive

The most popular is cement-based tile adhesive. If you need to lay the tile on a stable foundation - such as a concrete slab or screed - cement compositions are optimal in terms of price-quality ratio. They have a relatively low price and good performance. They are used for laying tiles, porcelain tiles and mosaics on solid bases - concrete, cement-sand screed.

The compositions are laid on a thin layer - for even bases, and with curvature - a layer up to 2.5 cm (LITOFLOOR K66). Thick tile adhesives are not very common. The styling is too expensive. It is cheaper to pre-putty the notches, cut off the humps. Having prepared the base in this way, significantly reduce the cost of tile adhesive.

Cement tile adhesive is diluted with water before use. The proportions of glue and water are indicated in the instructions and on the packaging

Cement tile adhesive is diluted with water before use. The proportions of glue and water are indicated in the instructions and on the packaging

Quick-drying cement adhesive can be used on prefabricated substrates, but after a primer that reduces absorbency. In some formulations, polymers are added to improve or change properties (to increase elasticity). But this is regulated by the manufacturer - where it is possible, which specifically, in what quantity. Cement glue is sold dry, before work, you need to add water and mix.

Cement tile adhesive is one of the most common. Even one manufacturer has a dozen species for sure. How to figure it out? In the labeling of cement compositions there are numbers. They show the strength of the composition. The larger the number, the higher the strength characteristics. Strengthening is achieved by adding polymers. And the numbers show the amount of additives.

The logic of numbers is maintained by any manufacturer of tile adhesive: the larger the number, the stronger the adhesive

The logic of numbers is maintained by any manufacturer of tile adhesive: the larger the number, the stronger the adhesive

For example, consider the popular brands of tile glue Ceresite. They have a ruler with the letters SM and different numbers. So here. СМ11, СМ14, СМ16 and СМ17 - the amount of polymers from one to another almost doubles. To make it clearer: in СМ16 there are two times more polymer than in СМ14. Therefore, CM14 is more “rigid” during operation, and its “adhesion” to surfaces is much less than that of CM16. Now it’s clear why the increase in the “number” increases the price of glue. The cheapest is CM11, the most expensive in this line is CM 17.

Dispersion adhesive

Dispersion tile adhesive is good in that you can put both large and small tiles. Paving of granite, natural or artificial stone is possible. The base is concrete, cement, gypsum, plaster, prefabricated bases, GVL, warm floors. Allows you to get a waterproof finish. It is sold in the form of a ready-to-use dispersion - in buckets of various capacities.

Dispersion glue - clean, durable, water resistant

Dispersion glue - clean, durable, water resistant

Floor tiles and porcelain stoneware are waterproof materials. But, if put on a regular cement tile adhesive, water will seep through the seams. In those places where the appearance of puddles is not very likely - in the kitchen, in the corridor - you can save the situation using waterproof grout.

Where water can stand for a long time - in showers, in wet areas of a bathroom, on a balcony - it is better to use dispersion glue. If you are looking for moisture resistant glue, see this category. He won’t miss the water for sure. Dispersion glue can be used in a shower cabin without a tray, bathrooms, for facing the pool, in the kitchens.

Two-component epoxy adhesive

The hardest thing to find is tile adhesive for wooden surfaces. Good adhesion is needed, and it is also necessary that the composition remains elastic after drying. Wood from moisture and temperature changes its size. Yes, and wooden floors can "walk" underfoot. For such cases, look towards the two-component tile adhesive.

Mix two-component tile adhesive before use

Mix two-component tile adhesive before use

Epoxy tile adhesive is suitable for laying any type of material on non-traditional substrates, such as plastic, wood. It has increased elasticity and excellent grip. "Tenacity" and elasticity allows laying tiles on metal, glass, tiles. The composition is resistant to vibrations, can be used for facing stairs and “walking” bases. There is no water in the composition, so it is recommended for substrates that are poorly resistant to moisture. The base can be a wooden floor, plywood, DSP, glass-magnesite sheet and so on.

Types of glue by area of use

It is necessary to choose glue taking into account operating conditions. Be sure to pay attention to this moment. Any compositions are suitable for rooms. But if you need glue for the floor in a seasonal summer house, in a bathhouse, in a gazebo, other objects on the street or in unheated rooms, you must still pay attention to the temperature range. For such purposes, tile adhesive for external use is suitable.

So, here is what gradation in special properties can be:

- for internal use,

- compositions for external use,

- resistant to aggressive influences,

- specialized, with improved characteristics.

When choosing, you need to look at the area of use, temperature and other parameters

When choosing, you need to look at the area of use, temperature and other parameters

A few words are worth mentioning about specialized tile glue. These are compositions with polymer additives that change / improve the properties of cement. For example, adhesive for floor tiles with improved adhesion is used when laying tiles on smooth substrates. Compounds that remain elastic after drying - for laying tiles on wood, etc. In the bathroom or shower, the kitchen needs increased resistance to moisture. Here it will be necessary to look for moisture-resistant adhesive for the tile. When laying on the street - on the porch, terrace, in the gazebo, in an unheated cottage - you will need frost resistance. There are also such compounds. In principle, any problem today has a solution. You can find tile glue even if you want to lay a tile on a tile.

Best glue for tiles

Choosing the best glue for laying tiles is another task. On the one hand, you don’t feel too expensive if you can manage cheap. On the other hand, you will save a little due to cheaper glue, and in a couple of years you will have to change the tile, because it “coils” or burst, or some other irreversible processes. Therefore, carefully approach both the choice of the manufacturer and the choice of a specific composition.In principle, the normal manufacturer in the description indicates everything that is necessary:

- for which tile - the size and type of tile, stone,

- on what basis

- what additional training is needed (if it is needed),

You also need to look at the comfort of working with the composition

You also need to look at the comfort of working with the composition

If you look at this information, it will already be good. It is important that the conditions are met for all points. Still important parameters such as the time of work with the mixture and the time to adjust the position of the tile. Of course, they depend on the density of the batch, the humidity in the room, the presence of drafts, but still, the longer the laying time, the easier. For beginners, this is very important.

Layer thickness

On the one hand, a thin layer under the tile is a low expense, which means less money for glue. But cheap glue is “weaker" in the sense that its strength is lower. And the weaker the glue, the worse it behaves on a thin layer. So laying floor tiles on a thin layer - only on expensive compositions.

The thickness of the adhesive layer for the tile is selected based on the curvature of the base, but not only

The thickness of the adhesive layer for the tile is selected based on the curvature of the base, but not only

For example, if the adhesive layer is 2-3 mm, it is worth taking glue of a higher grade. If you choose between Ceresit CM 16 and SM 14, a thin layer is better than 16. If the adhesive layer for the tile is 4 mm or more, you can take CM 14. And it's not just Ceresit. This approach holds true for other brands: tiled adhesive of a higher grade with higher strength is taken on a thinner layer.

Tile Size

In general, the cheapest glue is taken if the following conditions are met:

- tiles are laid in a heated room,

- on concrete or cement base,

- size no more than 250 * 250 mm,

- no floor heating,

- normal humidity.

The larger and thicker the tile, the stronger the adhesive should be

The larger and thicker the tile, the stronger the adhesive should beIf all these conditions are met, you can not worry and take cheap glue. But it’s better - cheap from a trusted manufacturer (Plitonite, Kreps, Osnovit). It may well happen that after drying the glue can be crushed with a finger. There are such fakes. If you do not know whether it is possible to trust a specific composition, before purchasing the entire volume, buy the minimum possible amount. Lock the house, put the test tile. In the process, evaluate how easy or difficult it is to work, see how long the mixture will “live” in the container where it was kneaded. After drying (the time is indicated on the package), evaluate the strength of the composition. If everything suits you, you can purchase the entire batch.

In general, the larger the tile, the stronger the need for glue. For the floor, the “lightest” adhesive is not used at all. If you look at the description, glue of medium grades and higher is used for laying on the floor. The division is:

- ceramic floor tiles up to 300 * 300 mm - the adhesive needs medium strength (SM 14 and analogues),

- natural stone, small-sized artificial stone, 400 * 400 mm porcelain tiles and medium-sized ceramic tiles - high strength adhesive is needed (SM 16 and SM 117),

Always see description

Always see description

All this is true for laying tiles without heating. If you put on the screed, but with heating, you need a composition with increased elasticity - when cooling / heating materials increase and decrease. In order for the tile not to crack or bounce, it is necessary that the adhesive maintains elasticity. Then he compensates for all the changes.

On a walking surface, warm floor

As already mentioned above, for a warm floor or surfaces that have significant thermal or humidity expansion (prefabricated screed) you need tile adhesive that remains flexible. And, anyway, even with such glue, it is better to use a small tile on the floor. Less likely to tear her up.

For laying on a warm floor or DSP, LSU and other similar substrates, the following compositions can be used:

- Roussean Fiksator, Stretchy

- LUGATO Flexible

- Knauf flex

- Litoflex k80

Separate products come for the underfloor heating. Adhesive for floor heating should be flexible

Separate products come for the underfloor heating. Adhesive for floor heating should be flexible

These are far from all possible options, but these are those that have shown themselves to be in operation, at least well, and even conveniently when applied. The list contains both cement-based compositions with polymer additives and dispersion compositions. Different price segments are presented. If your budget is limited, start at this position. If the budget is not too tight, or the amount of work is small, you can choose according to technical criteria. After there are a few that suit you in all respects, then look at the price.

Over waterproofing and tile to tile

If the base is treated with waterproofing, it is better to take the glue of the same brand. This is not necessary, but more likely to succeed. Especially if there is no experience. So you can be sure that the materials will be compatible.

- LITOKOL K80 and K81

- Weber Stone Fix

Often such coatings are called complex or unstable.

Often such coatings are called complex or unstable.

It is worth observing another rule - the more polymers in the waterproofing, the higher should be the brand of tile adhesive.

For marble, glass tiles and mosaics

The adhesive for laying marble, mosaics or glass tiles is different in that it is made on the basis of white cement. This component is very expensive, and since the composition also includes additives to increase strength, the price is not entirely humane. But other compositions - based on ordinary gray cement - cannot be used, as the color changes.

- ANSERGLOB BCX 46

- Vetonit mramor

- LITOPLUS K55

- Cerezit SM17

The adhesive mixture for marble and glass mosaic is made of white cement

The adhesive mixture for marble and glass mosaic is made of white cement

In general, serious manufacturers all have similar materials. Choose those that are available in your area. And, again, look at the operating conditions, layer thickness, viability of the solution, etc.

No. 1. What determines the choice of glue?

Masters know that there is no absolutely universal tile adhesive, although there is something similar on sale. In difficult operating conditions (for example, a bathroom), it is better not to use universal compounds.

The choice of glue is based on these three main factors:

- dimensions, material and features of the tiles used,

- surface type

- Operating conditions. There are adhesives intended for use indoors and outdoors, in conditions of high humidity, constant temperature drops, etc.

Modern adhesive compositions are mostly based on the same cement-sand mixture, only plasticizers and other chemical additives are added to it, which provide high adhesion.

Usually glue is available in dry mix, which must be diluted with a certain amount of water, but there are already ready pasty compounds, or mastics. Paste glue is produced on the basis of refined products, latex and some additives. It costs more, it is not very convenient in transportation, but indispensable when it is necessary to mount heavy large tiles or porcelain tiles, as well as when it is necessary to stick tiles on plywood or drywall.

No. 2. The main types of tile glue

Depending on the composition, tile adhesive can be of the following types:

- cement based

- epoxy

- dispersive.

Cement based adhesive - This is a classic of the genre. Dry mixtures are prepared on the basis of cement and sand, polymer and latex additives are added to them, receiving different compositions. The main advantage of such adhesives is low price. The cost of installing 1 m 2 of tile with cement-based adhesive is 20 times lower than when using epoxy glue, and 10 times lower than dispersion. Thanks to the many possible additives, you can prepare the composition that is most suitable for any operating conditions. This means that we can talk about a certain universality. In terms of assortment, such compounds are in the lead.Moreover, it is not difficult to find cement-based glue in any store in any settlement, it is relatively easy to apply, and any craftsman knows how to behave with cement glue, which cannot be said about other compounds.

Epoxy adhesive prepared from several components. These are epoxy-polyurethane resins, organic additives and inert fillers, to which an organic-based catalyst is added. The result is composition with unique properties. It provides heavy-duty connection of tiles with the surface, is not afraid of frost, high humidity, temperature changes, it does not shrink and withstands the highest loads. Minus - price: installing a square meter of tile on such glue will cost almost as much as the tile itself. Epoxy glue is used in places with maximum load: metro, airports, workshops and other premises.

Dispersion adhesive made on the basis of synthetic resins, with organic additives and an inert filler. The composition will cost less than epoxy, but still several times more expensive than ordinary cement. The main advantage is high ductility.Therefore, dispersion glue is indispensable when it is necessary to install the tile on a moving base, for example, wooden floors and walls. The composition is sold ready to use, it quickly sets and dries.

Since an ordinary apartment does not have such loads as an airport or metro, questions should not arise about which tile glue to choose - in almost all cases ordinary cement-based glue will be sufficient.

Separately, it is worth noting such a composition as liquid Nails. The material is based on polymers and synthetic rubber. In terms of performance, neoprene-based liquid nails have shown themselves best. The composition is not afraid of moisture, but has an unpleasant odor, and because of the increased content of toxic substances in residential premises it cannot be used. Safer water-based formulations do not have sufficient moisture resistance to be used for installing tiles in the bathroom. Typically, such glue is used only during restoration of the tiled coating.

Number 3. Tile Material and Features

Going to buy glue is better when the tile is already bought or it is precisely known what format it will be. The larger its size, the more requirements are put forward to the adhesive composition. To hold a heavier tile, the adhesive must have enhanced bonding properties. Pay attention to adhesion parametersindicated on each package of glue and expressed in MPa. So, for example, if we are talking about a small tile that will be mounted on a wall in a dry room, then glue with an adhesion of 0.2-0.3 MPa will be enough. If it is necessary to clad the facade with heavy large tiles, it is better to take glue with an adhesion of 1 MPa, and it should be frost and moisture resistant.

For styling floor tiles recommend taking adhesive with high elasticity. Elastanes and plasticizers in the composition of the material will talk about this.

Usually for the installation of all types of ceramic tiles, porcelain stoneware and artificial stone use gray glue. When it comes to glass mosaic, it is better to take the composition white color. It's not about adhesion (it does not depend on color, contrary to existing myths) - it's about aesthetics, which will be much higher when using white glue.

Number 4. Glue and operating conditions

For external and internal work, different glue compositions will be required. A special glue will be necessary even when it comes to operation in conditions of high humidity, frequent changes in temperature, frost, high mechanical stress. The most common cheap cement-based adhesive is designed for use in dry rooms without temperature extremes. They can carry out the installation of tiles in the living room, dining room or hallway.

For outdoor work produce special compounds that differ in frost and moisture resistance. Such glue is not afraid of frost, sun, rain and other negative environmental influences. It can also be used indoors, however, its use will be justified when its exceptional properties are really necessary.

For laying tiles on underfloor heating it is better to use elastic compounds. Such glue withstands linear expansion of the screed and does not crack, thereby prolonging the initial appearance of the finished surface.

Glue mixes for tiles are divided into the following groups:

- first group (C1) - these are compositions for external and internal works, which provide adhesion at the level of 0.5 MPa. Depending on which substances are included in the adhesive, it can be used in dry and wet conditions,

- second group (C2) - these are improved cement-sand mixtures, which include special substances that provide them with certain characteristics. The adhesion of such adhesives is at least 1 MPa, the elasticity is increased, and depending on the composition, it is allowed to use in places with very high humidity, constant temperature drops, as well as in the presence of serious dynamic and static loads,

- third group - These are special-purpose adhesives with specific properties. These are heat-resistant compositions with which you can glue tiles for facing stoves and fireplaces, white adhesives for the installation of mosaic, marble and translucent tiles, special adhesives for use in pools and other compositions.

No. 5. Choosing glue for installing tiles in the bathroom

Particular attention should be paid to the choice of adhesive for tiles in the bathroom. It must be moisture resistant composition, and he may possess fungicidal propertiesto prevent the development of fungus and mold. If the tile will be mounted directly on drywall, it is better to take a plastic composition. Prior to installation, the surface must be treated with a primer, otherwise it can absorb glue, as a result of which the bond strength will be weakened. Strongly absorbent places should be repainted with a primer. It is also better to use waterproof compounds in the bathroom for grouting.

Often in bathrooms it is recommended to use quick drying formulations, which after 3-5 hours are set and allow you to safely operate the tiled surface.

No. 6. Glue and type of substrate

All the bases on which the installation of ceramic tiles is allowed can be divided into two groups:

- simple groundswhich include concrete, brick, surfaces from cellular concrete blocks, sand-cement screed and other stable, solid, non-deformable surfaces,

- complex grounds easily deformed. These are wooden, plastic and drywall surfaces, as well as metal, glass and a layer of old tiles.

When choosing glue for tiles, consider the following recommendations:

- for a simple stable base you can take ordinary cement-based glue, compositions with latex additives are excellent,

- on the old tile, the painted surface and drywall installation is recommended to be performed using dispersion glue, but in the case of drywall, ordinary cement glue is often used, but with additives that increase its elasticity,

- if necessary, firmly fix the tile on metal or plastic basethen it is best to take epoxy glue.

Number 7. How to calculate glue consumption?

The approximate consumption of glue each manufacturer indicates on the packaging, and the exact consumption will depend on many factors. Only an experienced craftsman can accurately calculate the rate of glue consumption in kilograms of dry mix for each square meter of surface.

The following factors affect the consumption of the adhesive mixture:

- tile size. The smaller each individual tile element, the thinner a layer of glue is needed to secure it.So, for example, for mounting tiles with a format from 2 * 2 to 10 * 10 cm, the average consumption will be about 3 kg / m 2. For tiles ranging in size from 10 * 15 to 20 * 20 cm, the adhesive layer increases and the consumption is up to 4 kg / m 2. On a tile from 20 * 30 to 30 * 30 cm, it is necessary to apply a layer of glue even thicker, and the consumption will be about 5 kg / m 2. For the installation of tiles larger than 30 * 30 cm, you will need 6 kg of dry mix for each m 2 of surface,

- tile composition. If the water absorption of the tile is high, then it will absorb part of the glue, and its consumption will increase. For example, most types of ordinary wall tiles have a water absorption of 10%, while for ceramic granite this figure is only 1%,

- flatness of the base. The smoother the surface at the base, the lower the glue consumption. If you or the craftsmen were too lazy to thoroughly align the walls or floor, then get ready to overpay for glue. If the irregularities are too large, then the tile may even peel off soon,

- mastery of the one who does the work tile laying, may also affect the consumption of adhesive. If the glue leaves too much, it is worth doubting the professionalism of the performer,

- there is an opinion that even glue application tool, affects the consumption of the composition. Some say that a V-shaped putty knife will save glue, while a U-shaped one does less sparingly.

- parameters such as humidity and air temperature, ventilation and others.

Many manufacturers of tile adhesives on their sites have special calculators that help calculate how much a particular composition will be needed to lay a particular tile. When the approximate flow rate and surface area to be coated are known, you can easily calculate how many packages of glue are needed.

Number 8. Tile Adhesive Manufacturers

The installation of ceramic tiles is a responsible matter, and I don’t want the elements of an expensive tile to be damaged due to poor glue, and few people wish to redo the repair in a year and a half. That is why it is better to take glue from a trusted manufacturer, so as not to worry again.

Among the largest manufacturers of tile adhesive we can safely recommend the products of such companies:

- Ceresit Is the most popular adhesive on the market. The manufacturer's range is huge and includes standard adhesives for indoor and outdoor use (SM 9 and SM 11), elastic adhesives (SM 14 Extra, SM 16, SM 17) and special adhesives for porcelain and large-format tiles, mosaics and facade tiles. All formulations are absolutely safe, quality checked by numerous buyers,

- Knauf produces a series of adhesives that can be used for mounting tiles and artificial stone on any surface. There are compounds that are resistant to water and low temperatures, adhesives for exterior and interior use. The adhesion is in any case at a height

- Mapei - an Italian company, offers paste-like adhesives and dry mixes that cover almost all possible operating conditions and surface types,

- Litokol - Another Italian manufacturer that produces cement-based adhesives, dispersion and reactive compositions. You can list all the adhesives of the company for a long time - there is a suitable composition for any conditions,

- Sopro - a German company that offers white and gray adhesives, elastic and conventional compounds, quick setting and epoxy adhesives,

- Kilto produces glues, mainly in paste form. The compositions have a high degree of adhesion, but they are not recommended for use in rooms with a high level of humidity,

- Unis - One of the largest domestic manufacturers, has its own raw materials base in Perm and 5 production sites throughout the country, so the price of products of the same quality as that of foreign competitors is lower. All products are certified according to the most stringent standards.The range includes adhesives for indoor and outdoor use, compositions for laying tiles on inclined surfaces, on a warm floor, for the installation of mosaics and porcelain tiles, moisture-resistant, high-strength and flexible compositions.

Without good glue, it is difficult to perform high-quality tile laying, but even it will not save if an unskilled person takes on the job, so if there is no confidence in one's own strengths, it is better to call a professional for help.