PhD, site expert.

Entrance metal doors have two main tasks: to reliably protect the owners from intruders and create comfortable living conditions. Comfort, in turn, is always associated with heat in an apartment or house. Therefore, the insulation of the doorway of the entrance door is the primary goal of the owners after installing a new door unit. After all, he, along with windows, is the main conductor of cold in the room. It is necessary to insulate the box, door leaf and slopes.

In this paper, we consider in detail all the stages of thermal insulation of the box and door leaf. The nuances of the process of warming the slopes are discussed in detail in the material: “Finishing the slopes of the front door”, which makes it possible not to touch on this topic.

The choice of insulation for the front door

Insulation of the front door in an apartment or private house provides for several operations for thermal insulation of the doorway:

- technological gap insulation

- creating a thermal break in the frame of the door frame,

- thermal insulation of the door leaf inside and out,

- sealing gaps between the box and the drafts web,

- installation of second doors.

For each stage of work you need your own insulation.

Technological clearance warming

The distance between the wall and the door frame (technological gap) in the vast majority of cases is foamed with foam. At the same time, some experts prefer a cement-sand mixture, which in our opinion is not the optimal solution:

- cement mortar conducts heat better, which means that the path to the room will be slightly opened to the cold,

- throwing a solution between the box and the outer platband from the side of the apartment with a solution will require dexterity and patience, because the gap between the wall material and the iron block of the door is only 2-2.5 cm.

Door frame insulation

In all economy-class doors, the door frame is not insulated. The metal conducts heat well, which requires the creation of a thermal break inside the profile. For these purposes, you can use:

- expanded clay,

- sawdust,

- polyurethane foam.

For information: recently, for heating the door frame, a thermal cord is laid, which can be turned on and off at any time.

Of the materials listed, foam holds heat best, but it is also the most expensive. The use of bulk insulation is much cheaper, but there is a problem when filling them with horizontal structural elements. If the bottom profile is partially filled, expanded clay or sawdust wake up from the uprights, then filling the top becomes a problem that cannot always be solved. Foam has no such problems.

Conclusion: if the door is really insulated, and the processes of thermal insulation are not simulated, the insulation of the box should be mounting foam.

Installation of gaskets

Insulation of the front door in the apartment will not work if there are no seals on the narthex. On sale they are presented:

- rubber

- thermoplastic elastomers, also referred to as thermoplastic elastomers (abbreviated TPE),

- artificial rubber

- silicone

- foam rubber.

Each type of seal has its pros and cons, which are described in detail in the material: "How to replace the rubber seal on plastic windows?" (paragraph 4).

In this case, the insulation for the front door is best bought from artificial rubber or rubber. Silicone material is much more expensive with comparable specifications with the materials noted above.

Foam has a life of 4-6 years, after which it is deformed and passes cold air from the entrance.

Door leaf insulation

Thermal insulation of the door leaf is possible in two ways:

- The inner part of the door leaf structure is filled with insulation - technological reception is possible only with a removable sheet on the inside of the door (it is not welded).

- Thermal insulation material is mounted on top of the door from the outside or inside, which does not exclude a two-sided option of insulation.

In this regard, both general and specific requirements are imposed on insulation materials. As for the general, the materials:

- must be environmentally friendly

- have a low heat absorption coefficient,

- do not absorb water

- have an operational resource commensurate with the service life of the doors,

- be affordable to the mass consumer.

The specifics depend on the location of the insulation. So, when insulating the door with the help of upholstery, the insulating material must be elastic, capable of significant deformations, which is not the case with rigid foam insulation.

As a filler, foam plastic, expanded polystyrene (polystyrene foam), basalt cotton wool, synthetic winterizer, foam rubber, isolone and other materials have gained wide popularity.

Suitable for filling the inside of the door leaf Styrofoam. It has low weight (the door does not weigh down), high strength and wear resistance. The advantages must be attributed to a simple laying technology - it is easily cut to the size of the cells formed by stiffeners.

Enhanced polystyrene is gaining popularity - polystyrene foam (the Penoplex trademark). Many builders believe that this is one and the same material. In shape - yes, in fact, these are different heaters, as evidenced by their comparative characteristics.

- 0,036–0,050 W / (m · K) - foam,

- 0.028 W / (m · K) - expanded polystyrene.

As can be seen from the comparison, expanded polystyrene with a smaller thickness holds heat better.

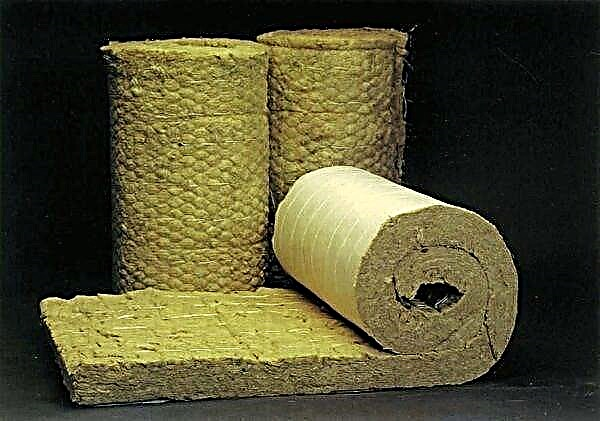

Basalt wool - one of the rare building materials, which is difficult to find flaws. Him:

One minus - when wet, dramatically loses the ability to protect the apartment from the cold. This is not a problem for apartments, and for private houses in rural areas (dachas) and the city it is better not to use it, since in winter the door freezes outside and warms up from the inside, as a result of which condensation forms inside the door leaf, reducing the thermal insulation capacity of basalt cotton wool by 10 -fifteen%.

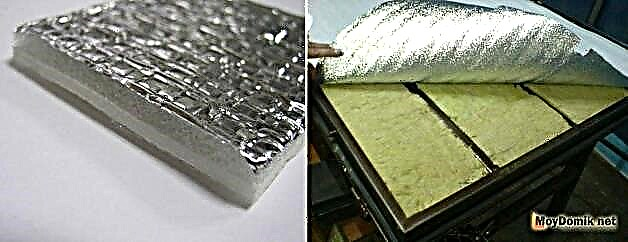

A very effective insulation material is isolon - the result of foaming polyethylene with propane. Him:

- very good thermal insulation performance,

- low water absorption - less than 1%,

- increased flexibility and elasticity

- simple laying technology

- low specific gravity

- high service life - up to 100 years.

Among the minuses, a very high price should be noted.

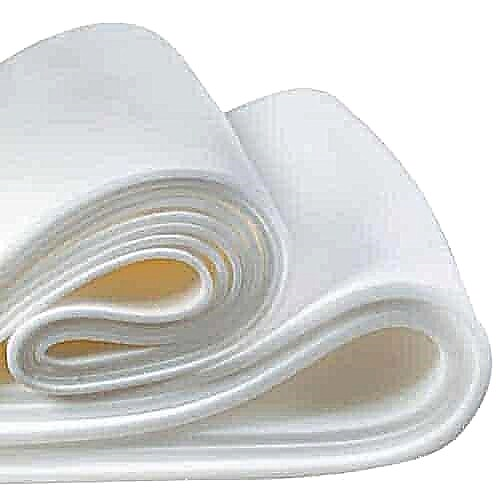

Synthetic winterizer It is a light, voluminous, elastic non-woven insulation in which synthetic fibers are bonded with glue or thermally. However, its use is justified only in apartments - when the outdoor temperature drops to –10 o C, it becomes useless.

Widely used for door insulation and elastic foam rubberconsisting of 90% of the air. It has excellent thermal insulation properties and easy installation. The disadvantages include fast flammability, a shorter service life and difficulties in transportation - it cannot be compressed, as the original quality characteristics are lost.

Do-it-yourself insulation of the entrance metal door can be done with isolon, foam rubber, mineral wool obtained from basalt and batting.

Batting, as a heater, did not find wide application in construction. But for door upholstery it fits almost perfectly. Only knitting and piercing material is used, in which:

- high level of thermal insulation, both from low and from high temperatures, which is not the case with synthetic materials,

- ability to absorb noise of various origins,

- environmental friendliness - made from natural fibers, mainly from wool.

Weaknesses include:

- high weight - specific gravity 200-400 g / m 2,

- the ability to absorb water in large quantities,

- uneven distribution of fibers during door operation, resulting in areas with a thick and thin layer of material.

For technological clearance

To seal the space between the door block and the wall you will need:

- mounting foam in tubes,

- masking tape

- polyethylene film,

- knife or scissors

- construction foam gun.

For information: each spray can has its own spray bottle. But working without a gun is in many cases difficult. Therefore, professionals take their use for granted.

For internal warming

Replacing the door leaf filler requires the following materials and tools:

- thermal insulation material

- plastic film for waterproofing insulation,

- wooden blocks

- screws

- glue

- metal corners for stiffening the box of bars

- electric drills with a set of metal drills,

- construction knife

- scissors

- small tooth wood files,

- screwdriver or Phillips screwdriver,

- awl or thin nail,

- sandpaper P60.

Attention: how to insulate the entrance metal door in the apartment with the help of upholstery, is described in detail in the article: “Upholstering doors with dermantine with your own hands”. Therefore, the technology of external insulation in this material is not advisable to consider.

Technological clearance

The doorway insulation in the area of the technological gap is carried out in the following sequence:

- from the side of the room, the box and door are closed with plastic wrap and masking tape - the tape is glued to the steel profile of the box, the film covers the door leaf,

- the gap is abundantly wetted with water from a spray bottle or plastic bottle. Installers will say that this removes dust. In fact, spraying is carried out for another purpose: to give the foam moisture to improve its structure, the polymerization process is much faster and better at high humidity, the foam does not fall off from a wet surface,

- the can is shaken and flipped over. Through a thin tube, a small portion of the foam is applied to the back of the outer clypeus in a continuous strip. Work is carried out from the bottom up. Performing the operation in two steps will not allow the foam during expansion to exit between the metal platband and the wall from the outside of the doors,

- the work is carried out in two steps, which prevents the foam from expanding between the metal platband and the wall from the outside of the doors. 15-20 minutes after the foam has gained volume, the rest of the gap is foamed, but not more than half of the remaining free space,

- after polymerization of the foam, the protective materials from the doors are removed.

Important: the foam sticking out from under the box must be cut off immediately, and not wait for it to completely harden. At the same time, shallow oblique cuts should be left on the cut surface, which will relieve excessive pressure on the box and accelerate the hardening process.

Door frame

Insulation of the frame of the box must be done before installing the doors. To do this, partially use the holes for the anchor bolts, and where they are not enough, drill a drill. The diameter of the drill should allow the foam cylinder tube to freely enter the frame.

The distance between the holes is preferably maintained at 45-50 cm. Drill from the outside of the ends. Fill the inside of the door frame from bottom to top. Before work, the holes that go inside the box are sealed with masking tape (the door leaf is protected from foam).

Narthex

The technology for gluing the sealant can be found in the work: "Soundproofing the front door with your own hands." Here we dwell on some of the nuances that were not reflected there.

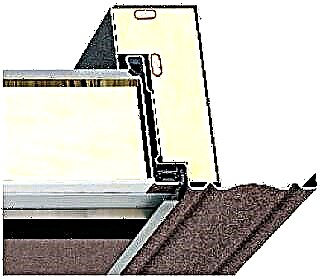

The profile of the sealant is selected depending on the size of the gap. For large gaps, a seal similar to the Latin letters O and D is better. For gaps of 3-5 mm, a section resembling the letters V or P. is suitable. And for small gaps, you must buy a C- or K-shaped seal.

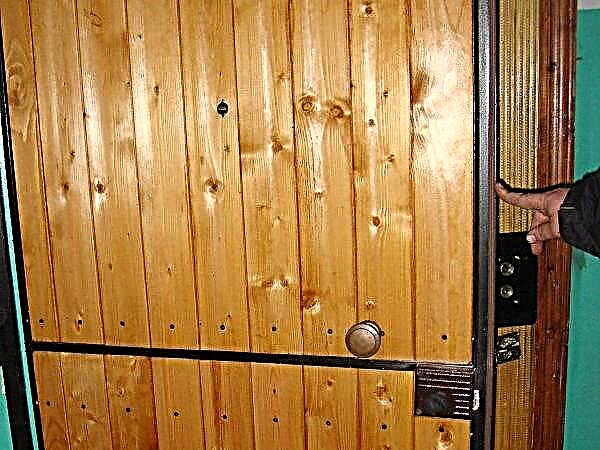

Doors inside

And now we will consider how to insulate the front door in a Chinese-made apartment. Immediately, we note that there are two problems that should be solved in a complex:

- no stiffeners

- corrugated cardboard serves as a filler, which is considered nominally insulation.

The work is carried out in the following sequence:

- the handle and locks are removed from the door, while not only external elements, but also locking mechanisms,

- the door is removed from the hinges and laid on a table or floor,

- twist the screws on which the inner sheet of the web is held,

- the sheet is removed and set aside,

- the interior space of the structure is measured,

- a lattice is assembled from a wooden bar, which should fit tightly into the frame of the canvas. To give rigidity to the corners of the frame, a screed is made - metal corners are attached,

- stiffeners are installed in the grill: two vertical and three horizontal. When installing them, the main thing is not to get horizontal bars on the handle and locks,

- at the place of installation of the lock mechanism, a wooden block is cut out,

- on metal in several places glue is applied by points - the more such points, the better,

- under the inner size of the canvas, with an overlap of about 10 cm, a plastic film is cut out and covered with metal. In places with glue, it is firmly pressed to the sheet,

Attention: the film does not fit under polystyrene foam (penoplex).

- the crate is laid on the film,

- under the size of the cells, the insulation is cut out and placed in the cells of the crate. So that the material does not move during the operation of the door, it is glued to the film and wooden planks. If size errors occur, if gaps form, they are filled with foam. The polyethylene inlet is wrapped on a crate and fixed to it with a stapler or glue,

- in the locations of locks and handles, the insulation is cut,

- the insulation material, together with the lattice frame, is closed by a film on top, which is attached to the tree,

- the cracks between the crate and the frame are filled with foam,

- the set sheet of the door leaf returns and is fastened with screws,

- put a handle and locks,

- the door is hinged.

Doors outside

Some models of Chinese doors are non-separable. In this case, they are insulated from the outside. It is possible to sheathe them with a leather substitute with a large amount of insulation between the door and dermantine, but in this case the problem of the rigidity of the web frame is not solved.

The problem is solved as follows:

- all protruding parts of the handle and locks are removed from the inside of the door,

- the door is removed from the hinges and laid on the floor with the outer side down,

- its width and height are measured,

- a crate is made from a wooden bar with a cross section of 20 * 20 mm - the large dimensions of the bar will make it difficult to access keyholes,

- stiffeners are installed,

- the grill is fixed with screws to the door,

- cells are filled with insulation.

The process of finishing the interior of the door with a panel of MDF, PVC or laminated fiberboard completes the process.

Conclusion

Door insulation can improve living conditions in a house or apartment. In this case, the work must be carried out comprehensively, installing thermal protection:

- technological clearance

- slopes

- door frame

- the narthex

- door leaf.

The technologies are not complicated, the whole cycle of work can be done independently. Small difficulties can arise only when choosing a heater.For the technological gap and the door frame, the best option is mounting foam, slopes - cement-sand mixture, the narthex - a rubber or rubber sealant, door leafs - foam for internal insulation and batting for upholstery with dermantine.

Door frame insulation

Insulation of the entrance metal door should begin with the elements of the box. If the box is made from a corner, then the insulation can only be made at the junction of the box with the doorway. In this case, the gaps are filled with foam, and excess insulation is cut off with a construction knife. If the box is made of a pipe of rectangular or square section, the insulation is placed inside the profile.

The better to insulate

To warm the door frame, use mounting foam or bulk insulation (sawdust, expanded clay).

Polyurethane foam It is used to eliminate gaps between the box and the doorway, as well as to fill the cavities of the box elements made of profile.

Loose heaters apply only to profiled frames. Profile filling occurs through a technological hole drilled in the upper part of the box. The diameter of the hole should allow the largest fractions of the filler to pass.

This method has a significant drawback: it is impossible to ensure that the bulk space of the box is filled with bulk materials. As a result of uneven filling, voids are formed that freeze. Therefore, the use of bulk insulation is possible only in production conditions, when assembling the box in the workshop.

Instructions for insulation

To fill the door frame with foam, it will be necessary to prepare technological holes in increments of 500 mm. Through these openings, the internal space of the profile is filled with foam. Excess foam escaping through openings must be removed with a construction knife.

The cracks between the door frame and the doorway are cleaned from the old insulation, moisten and fill with foam. Excess foam is removed using a construction knife, after which the place of contact between the box and the wall is masked with putty.

What is the heat lost from?

The modern metal entrance door is actually a complex structure, where iron is just a shell. The cavity of the web can be filled with insulation, since the main function of the door is to keep heat. But often there are leaks of heat and not only in private homes, but also in apartments. In addition, inexpensive metal doors as a case have ordinary tin, and instead of insulation - cardboard honeycombs.

Causes of heat loss in the house:

- Thin walls. The walls folded in the classical way several decades ago, which have no insulation, begin to freeze over time. From this, the insulation of the house is deteriorating.

- Cracks and crevices. When a heavy structure shrinks, cracks form on the walls, which eventually, if you do not pay attention to them, turn into huge gaps. Such gaps are also called cold bridges.

- Technical solutions (old doors and windows). Over time, the wood dries up, thereby forming enormous gaps in the box. Windows that are not properly insulated are one of the key sources of heat loss. And the door, if it is made of a sheet of metal and does not have the necessary insulation, or a poor-quality Chinese construction, inside of which instead of a heat insulator cardboard is the immediate cause of colossal heat loss.

therefore door insulation is an important component of thermal protection of the entire house. But before you realize the idea, find out the exact reasons for the loss of heat, so that it doesn’t turn out that you spend time and energy on warming the doors, and the reason for the uncomfortable microclimate lies in the cold bridges formed through the cracks in the house.

Important! The thickness of the iron door leaf is not an indicator of the thermal insulation of the door. A thick layer of metal is, first of all, protection against penetration and only then a heat insulator (provided that there are no gaps in the structure).

Choose a heater

The insulation on the door not only protects the room from the cold, but also isolates the room from extraneous noise, which is quite true in apartment buildings. Therefore, when choosing a finished door structure, it is worth asking about its content.

Penofol equipped with a foil layer with reflectivity, due to which all the heat remains indoors. But it is used, as a rule, only as an auxiliary insulating material.

Sheet heat insulators (foam, foam, etc.), good in ease of installation and low cost. Since the material is not hygroscopic, it is not necessary to mount a vapor barrier and moisture barrier membrane when installing it.

When choosing a hard insulation, give preference polystyrene foam (polystyrene). He is significantly denser and tighter polystyrene, moreover insulates more efficiently.

For rolled or sheet soft heat insulators glass wool and mineral wool. They differ only in the basis, their thermal insulation characteristics are approximately the same. Material environmentally friendly, non-combustible, allows you to independently choose the height of the stack, excluding additional trimming. These advantages make cotton insulation especially popular.

Material is sold in rolls or plates. Elements of any shape and size can be cut out of cotton wool, and to reduce the thickness of the insulation layer, it is enough to press and fix the material.

Lack of cotton wool - high hygroscopicity. The material is afraid of moisture and if the insulation absorbs water, it loses its heat-shielding properties. Experts do not recommend using this insulation for doors, since with a high contrast of external and internal temperatures, the likelihood of getting wet insulation is extremely high. However, the option is quite acceptable for the front door to the apartment.

Polyurethane foam fills all the cracks without being particularly expensive. You can spray it yourself, using a foam gun or inviting a specialist using a special spray gun to help.

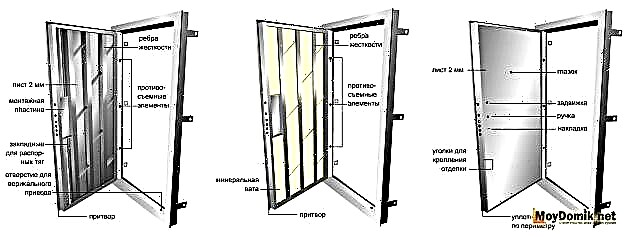

Factory "luxury" doors are insulated with three options for heat insulators:

- key insulation - Styrofoam,

- penofol is an auxiliary protection

- polyurethane foam the cavities of the door frame and stiffeners are filled.

In construction markets, you can often see insulation kits for entrance doors. Insulation and finishing material are already measured and cut to standard, but such sets are of little use, as they include thin layer synthetic winterizer or foam rubber and dermatin.

Tools and materials

In addition to insulation - the main material, we also need fasteners, cladding, etc.

Table 1. All necessary materials and tools

| Materials | Tool |

|---|---|

| Any selected insulation | Mounting tape |

| Polyurethane foam | Square |

| Hardware, liquid nails or polyurethane foam (for mounting a rigid heat insulator) | Pencil |

| Chipboard materials or lining (for sheathing a non-folding door) | Long ruler or rule |

| Adhesive tape, hydro and vapor barrier membrane (in the case of using a soft insulation) | Jigsaw or Saw |

| Dermantin, MDF or plastic (as a decorative finish) | Screwdriver |

| Rubber or silicone polymer sealant | Putty knife and mortar tank |

| Universal mounting glue (with good ability to adhere surfaces of different colors) | Foam gun |

| Putty for insulation of the door frame | Stapler |

| Staples for staples or furniture nails | Hammer |

| Dry wood beam for the implementation of the inner frame of the door leaf in case of its absence | Construction knife |

Prices for popular models of screwdrivers

Important! If glass wool is chosen as the main insulation, do not forget to take care of protecting the skin of the hands, organs of vision and breathing, using glasses, gloves and a respirator. When working with material, dangerous microparticles (fragments of fibers) are released, which, penetrating the respiratory tract, can cause prolonged irritation of organs.

We warm a door frame

The box of the metal door leaf is made of an iron corner, which is mounted in the opening with anchors. Between the mounted door frame and the supporting wall or partition, after removing the old door structure, often considerable gaps remain. Builders during installation blow them with foam, but it has a certain drawback: material is afraid of sunshine. If you do not hide sections of the foam from the ultraviolet in time, it will crumble into dust over time.

If the foam on any surface acquires yellow or brown, it means the material begins to break down.

How to do it right:

- We clean the wall adjacent to the doorway from the remnants of the mounting foam, embroider the plaster to brick or concrete and remove the dust.

- We spray the surface with plain water and foam the visible recesses. It will be better to stick foam to the wetted wall.

- When the material hardens, we cut off the excess.

We warm a door leaf

Before warming the iron door, the structure must be disassembled. To do this, remove the peephole, door handles, locks and lining.

When the canvas is fully prepared, do not forget to wipe it from dirt and dust before starting work.

Step-by-step door insulation algorithm

Table 2. We insulate the door

| Steps description | Photo |

|---|---|

| Step 1. If the canvas does not have additional stiffeners creating an internal frame, the skeleton must be assembled from wooden battens. The frame around the perimeter of the door and along the crossbars is fixed to the screws. It is important to choose a thickness of the bars so that they are not wider than the protruding elements of the door leaf. | |

| Step 2 Between the bars of the frame in the resulting cells we lay a heater. Consider the characteristics of the material and the need for additional membrane insulators. |

|

| Step 3 It is possible to fasten a heater on glue directly to a door or alternatively to bars. The most reliable fastening will provide a combination of both methods. Lubricate the door leaf with adhesive, apply insulation to it and press it tightly. If the insulation fits snugly into the cell of the frame, then it will be firmly fixed in place. |

Door Seal and Door InteriorThe design of the front door from the inside performs several functions. This is the insulation protection from mechanical influences and other damages, additional heat and noise insulation, as well as a decorative component.

A number of requirements are set for door leaf interior decoration:

In most cases, the metal door is sheathed inside with laminated particleboard or MDF, plastic or lining, wood or metal, plywood or OSB in combination with leather or dermantine.

Consider the interior design algorithm of an insulated iron door using hard sheet materials as an example:

The final step is the installation of a polymer seal to prevent the penetration of drafts through the cracks around the perimeter of the door. To do this, the surface of the door leaf and the frame is degreased, the protection is carefully removed from the adhesive layer of the sealant, the material is applied to the door and pressed. It is important to be careful when installing the seal, as the material is very thin and requires patience during installation. Features of insulation of a metal split doorThe algorithm for warming a metal split door is not much different from the process of thermal insulation of a conventional iron door leaf. The key role is played by the design feature of the door.

The door is removed from the hinges, laid on a horizontal surface, dismantled all the functional and decorative elements in the form of an eye, handles, locks and plugs, then dismantled the inner lining (if the product is not monolithic, then the finish is mounted on self-tapping screws). In the case of insulation of a non-separable door, the inner lining can be carefully cut with a grinder. When the product is disassembled, cardboard is removed from the cavities and the door is cleaned of debris and dust.

Next, equip the hydrobarrier, cut and fix the insulation (remember that moisture protection is not required for some materials). The insulation process itself is as simple as in the example with a one-piece door. Replace the pad. If after dismantling it has become unusable, the interior design of the door can be replaced. Then the peephole, locks and handles are fixed in place and the product is installed in the box.

In the case of a monolithic door, if there is no particular desire to spoil its integrity, you can insulate it on top of the existing skin. To do this, on the demonstrated and disassembled door leaf from the inside and outside, a crate of timber is attached. All further actions are practically no different from previous algorithms. What to considerIn addition to thermal insulation of the door leaf itself, the process of door insulation includes other important nuances.

Polymer sealing tape will help improve the quality of thermal protection of the door. Such material is supplied in rolls, sold per meter. Installation of the tape is extremely simple: the sealant has an adhesive edge, with which it is attached to the door and frame.

Very effective is the insulation of the doorway itself with foam. This can be done even if there are no signs of material destruction in the cavities. Blowing out voids with foam, and then plastering the wall is not difficult, but will significantly increase the efficiency of insulation.

The thickness of the door insulated from the outside, as a rule, increases. Consider this fact when installing the locks: you may need to replace them with structures with extended keys.

Another source of heat loss is indoor door slopes. If they are not framed or fast-sewn, they should be given attention. Remove the old finish, blow out the cavities with foam. If the space is spacious enough, fill it with another heater and fix the finish. Common mistakesEveryone can step back: an experienced installer or a beginner home foreman. When warming a metal entrance door, there are a number of common errors that are most often allowed.

The metal door insulated in accordance with all the rules, in addition to armor from villains, will also reliably protect the house from extraneous noise and pervasive cold. In addition, insulation provides protection of the canvas itself from corrosion and, accordingly, increases its service life. Use the materials that are available to you and do not be afraid to make a mistake, because only the one who does nothing is not mistaken.

Warming MethodsYou can, of course, insulate the door simply by sticking insulation around its perimeter, but there will be no big effect - it is still worthwhile to insulate in accordance with the professional rules of thermal insulation work. For this, it is worth considering that all heaters can be conditionally divided into groups: They fully meet the touch and appearance of these criteria. So the first group includes: polystyrene foam and polystyrene foam (polystyrene foam), the second - glass wool and mineral (basalt) cotton wool. All these materials are distinguished by special qualities - for effective warming :

Choose the most effectiveAlthough all of the listed materials warm the rooms well, but not all of them are suitable for warming the metal front door with your own hands.

So, the most effective way to warm an entrance door made of metal with your own hands is a combination of 3 materials:

Such a door will definitely protect you from the cold and eliminate the loss of heat in the living room. All the usual materials - dermatin, foam rubber or synthetic winterizer - are not suitable for decorating and insulating a metal door. Step-by-step instruction

Helpful information? Don’t forget to like and subscribe to the channel "Facade Expert"! PenofolDue to the reflectivity of the foil layer, it holds almost all the heat in the room. It is used only as an additional material.

Hard insulationThese include polystyrene foam and polystyrene foam (polystyrene foam). Their advantage is ease of installation, relatively low price. Since it is not hygroscopic, it does not need additional films. This is the only suitable option for installation in a cottage, country or rural house. Indeed, in this case, the door serves as a barrier to low temperatures and wind, which is not observed in apartment buildings, where the door goes into the entrance.

Soft heatersGlass wool and mineral (basalt) wool are included in this category. Their difference is only in the feedstock, in terms of their thermal insulation characteristics they do not differ much. Minvata is characterized by environmental friendliness, fire safety, the ability to vary the stacking height without additional trimmings. Cotton wool is sold in rolls or sheets, which makes it possible to cut from it workpieces of the desired size and lay them in cells formed by the stiffening ribs of the door itself. To ensure the desired height (insulation thickness), it is enough to simply press the material down (press the cotton wool), the thermal insulation properties will not suffer. But cotton wool has a drawback that does not allow recommending it for installation in iron doors for private homes. Because different temperatures act on different sides of the door, and sometimes the difference is up to 40 ° C (-15 on the street and +25 in the house). This leads to a shift of the dew point inside the insulation, and the cotton wool gets wet. It is possible to neutralize the effect by installing a hydrobarrier film. But, nevertheless, professionals do not advise performing warming of the iron door with cotton wool in a private house. It can become an acceptable option only if the front door in the apartment is insulated, since in this case there is not such a big difference in temperatures (the entrance is much warmer than on the street).

Inflatable insulationIt is represented by polyurethane foam. Spraying makes it possible to fill all the cracks, but at a high price.

Thermal insulation of metal doors of the "Lux" class is carried out using three types of material: polystyrene (basic material), polyfoam (optional), polyurethane foam (filling the voids of stiffeners and boxes). Additional materials for door insulation

From the tool you will need: roulette, drill, jigsaw, screwdriver, pencil, stationery knife. The frame device inside the door (stiffeners)After the door leaf is disassembled, it may turn out that there are no stiffeners in the door cavity, then they will need to be made. To do this, use a metal profile or corner with dimensions corresponding to the thickness of the door. Its widespread use is due to the fact that metal is easier to weld to the metal surface of the door. However, many masters agree that it is better to use a wooden beam, because wood has lower thermal conductivity. The difficulty when working with timber is that it is difficult to fix it securely enough and at the same time not damage the front layer of the door leaf.

How to insulate a metal front door in a private houseThe technology of warming a steel door from the inside will be described in several stages, in the form of step-by-step instructions, so that even without experience in construction, you can do the work yourself.

How to insulate a metal door with polystyrene foam - video

The result of all the work will be an insulated metal door, which will reliably protect the premises from heat loss. Now it can be hung back on the hinges and perform a functional check of the handles and the lock. But, it is worth noting that the insulation of a metal door only in the area of the door leaf is a small part of the possible work on thermal insulation of doors. One of the sources of heat loss is the door frame. In most cases, it is hollow, which means that it passes heat well. Insulation of the metal door box

It is easy to do. It is enough to drill holes in the profile of the frame (not through) at a distance of 400-450 mm. The diameter of the hole is equal to the diameter of the tube from the foam bottle. After that, the tube of the cylinder is brought into the profile and the foam fills the free space. Material prepared for the site www.moydomik.net Additional insulation of the entrance metal doorIn addition to the work performed, there are two more directions through which heat goes out (blowing from under the entrance iron door):

All work on the insulation of street or apartment metal doors can be done independently. But if you are afraid to make a mistake, it is better to order the services of a wizard. The cost of his work will be from 1,500 rubles. (excluding the cost of the material). And the final price will be determined taking into account the type of door, the complexity of dismantling one side of the door leaf, the presence of stiffeners, the type of sealant and the type of finishing material. However, the costs of warming metal external doors are always justified, since they entail a significant reduction in heat loss through the doorway and avoid the occurrence of condensation on the door surface, which leads to the destruction of the door leaf. InsideTo place a heater inside a metal door, you will need to perform the following steps:

Filling the joints between the insulation and the frame.

OutsideIf necessary, sheathe eco-leather steel door from the outside, perform the following work:

To obtain a decorative surface, you can additionally fix the material on the door surface using special self-tapping screws with figured heads. How to insulate a door if it goes outsideIn private homes or cottages, there is also a need to insulate a street iron door. Given that the door is constantly affected by weather changes and seasonal changes, it is necessary to responsibly treat the material that will be used inside the door leaf. The following materials are suitable insulation for a street door: These materials have minimal hygroscopicity, so temperature and humidity differences will not affect their thermal insulation properties. The process of warming street metal doors does not differ from the process of working with apartment doors. Korovin Sergey Dmitrievich Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction. |

Insulation of a metal door with penofol

Insulation of a metal door with penofol Warming of a metal door with polystyrene foam and polystyrene foam (polystyrene)

Warming of a metal door with polystyrene foam and polystyrene foam (polystyrene) Insulation of a metal door with mineral wool

Insulation of a metal door with mineral wool Warming of a metal door with polyurethane foam (PPU foam)

Warming of a metal door with polyurethane foam (PPU foam) The scheme of insulation of a metal door

The scheme of insulation of a metal door The layout of the stiffeners of the metal door

The layout of the stiffeners of the metal door Insulated door frame The door frame is insulated by blowing mounting foam into the metal profile.

Insulated door frame The door frame is insulated by blowing mounting foam into the metal profile.