A fence is a decorative element that serves to aesthetically decorate a local area. The first impression of your home depends largely on the external surroundings. Therefore, the choice of fencing must be approached with all responsibility. Beautiful, original wrought-iron fences will add solidity to your mansion, add sophistication and nobility.

Forged fences from the manufacturer

Forged products for the fence of the site is an expensive design, the price of the fence is set depending on the model chosen, the volume of manufactured products. But the high cost is justified by the fact that the forged structure will last more than one year and is characterized by high strength characteristics.

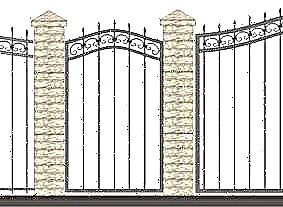

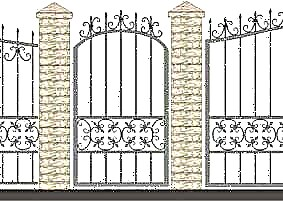

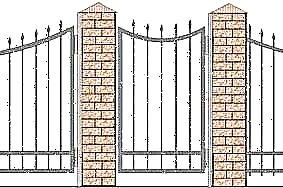

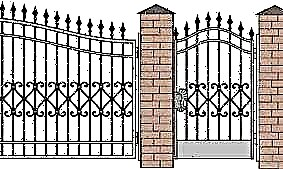

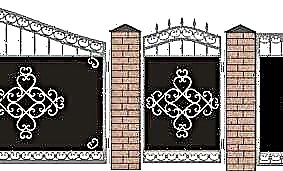

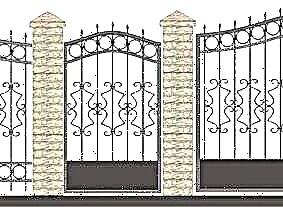

Examples of forged fences made by us

Forge "A-forging" is a company whose main activity is the production of forged products that can serve as a fence for the site, as well as be part of the decoration of the interior space of the premises. They can be used as an original insert for stair flights indoors.

The advantages of our products:

- Reliability. Thanks to repeated hardening, the design becomes durable, able to withstand any weather and mechanical influences,

- Long service life. This is proved by time, ancient mansions, which are historical monuments, always adorn wrought-iron fences that have been standing for several decades,

- Security level. The metal fence is difficult to damage. Penetrating intruders into the territory near the house through the gaps of the structure is not easy, since it contains many small details in the form of weaves and delicate patterns,

- Easy to care. High wear resistant properties. If the paintwork is damaged, then repairing the damage is not difficult. It is enough to clean the damaged area with sandpaper or a hard brush, degrease, prime and coat with a new coat of paint,

- External presentability and appeal

- A wide range that will allow you to choose a fence, taking into account your wishes, requirements and features of landscape design. To select a suitable option, you can view our catalog, where photographs and sketches of metal products made by our specialists are placed.

You can order your favorite model at any time convenient for you. To do this, you need to contact our managers and discuss all the details of the future project. Our masters will prepare an individual sketch or perform a fence selected by you from the catalog. If you decide to buy a forged fence for a summer house or a private house, call us, we will execute your order as soon as possible, taking into account the requirements and wishes.

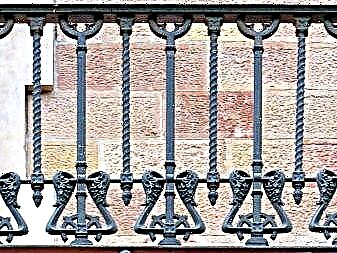

Railings with forged parts

Fences of this type are elite and stylish designs that remain at the peak of popularity.

Despite the high price compared to standard fencing options, the demand for fences decorated with forging remains high. They are used to equip not only country houses, as well as office buildings, estates of wealthy people, luxury hotels and other facilities.

Metal parts successfully combine functionality (benefit) and decorativeness. Fences with forged parts have always been famous for their exquisite appearance, practicality and durability.

Such products harmoniously fit into various decorative stylistics, modern and classic. A wide range of materials is used in the manufacturing sector.

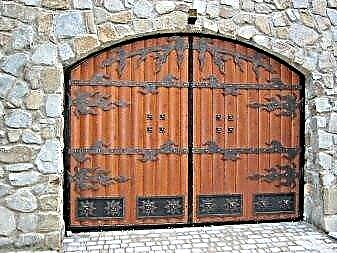

Forged elements are in harmony with various materials, acting as the basis: stone, brick, wood, metal.

Beauty

Appearance of products is the first advantage that should be paid attention to. Chic, sophistication, attractiveness - all this is inherent in the forged elements. Despite the fact that metal is a heavy and durable material, in the form of jewelry it turns into a light and weightless matter.

Reliability

A carefully crafted part has an almost eternal life. By installing forged parts once on a fence, you will enjoy their appearance from season to season. The main thing is to correctly install the element and do not forget to treat it with a protective compound if necessary.

Strength

Long-term loads, strong wind, snow, rain, dry air, scorching sunlight - all this and much more does not affect the forged parts. Quality products demonstrate reliability, practicality and resistance to various external factors.

If the cost of finished forged fences is not affordable for everyone, then almost every buyer can purchase individual elements. Depending on the material possibilities, the client can order a certain amount of jewelry.

Diversity

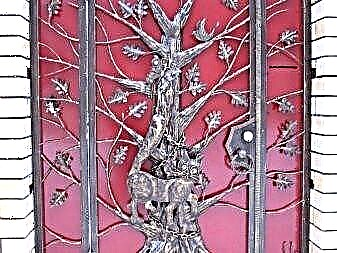

A huge selection of elements makes it possible to choose the perfect option. Animals and birds, abstractions, strict geometric shapes, floral ornaments, butterflies, various patterns and much more. The sizes of the elements may be different.

They also differ in color. Professional designers create whole artistic compositions.

Protection

The fence is supplemented with additional details to increase the level of protection. For this, various tips and much more are used. The functional features of the elements will be discussed later.

Local repair

If one of the elements breaks off during operation, it is easy to repair it.

If the breakdown cannot be fixed, you can replace the part with a new one, fixing it in the right place. Repair will take a minimum of time, given that there is no need to dismantle part of the fence.

Architectural stylistics

Art forged parts are made in such decorative directions:

- baroque,

- modern,

- avant-garde.

Modern masters experiment with different styles, combining them in one product. Optional forging must be performed in strict accordance with the architectural direction. Mixing styles creates unique and original forms.

All commercially available parts can be divided into two groups:

- Decorative elements. The name speaks for itself. The main task of such elements is decorative. Additional parts are used to give the fence more expressiveness and attractiveness. The shape, color and theme of the element can be varied. She is chosen in accordance with the general style of the exterior and the wishes of the customer. The figures are mounted not only on the fence, but also on the fence gate.

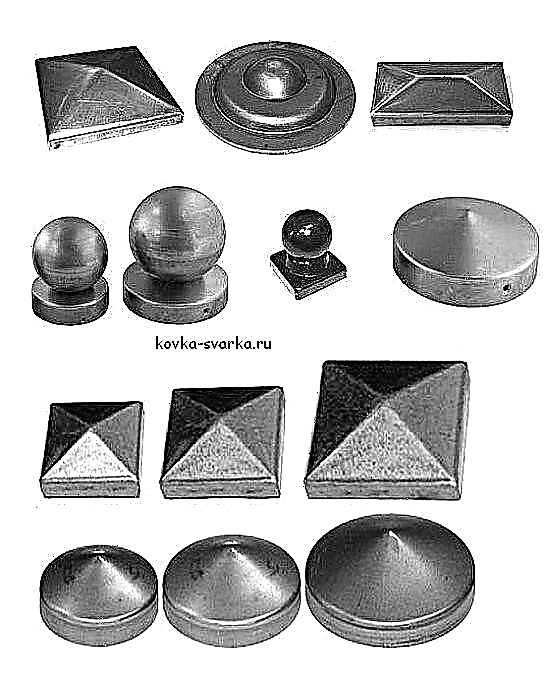

- Additional (additional). These are functional additions that are designed to protect the fence from negative external influences and increase the level of security. These include: caps, lugs, parapets, tops (they can perform both aesthetic and functional tasks). They are used on fences of various types from a variety of materials.

Most often, tops and tips are used as additions to brick fences and fences from a profile pipe.

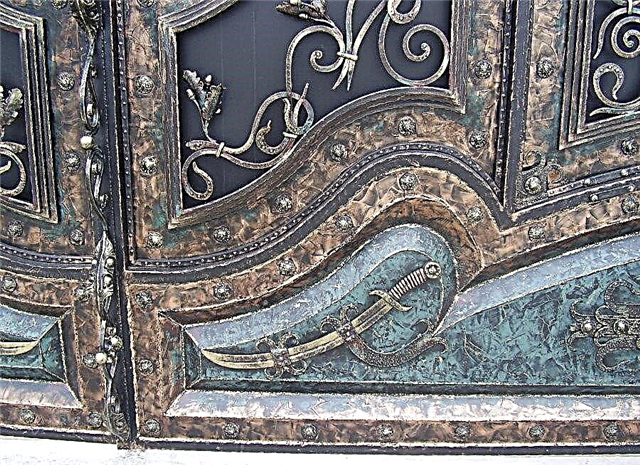

Manufacture

Creating metal jewelry and accessories for fencing is a complex and time-consuming process that requires special skills and knowledge.

Handwork - art forging

Due to hand forging, the most stylish and high-quality decorative elements are created. Using special tools and equipment, the craftsmen give the metal a certain shape. To make the products look as realistic as possible, they are supplemented with small elements.

This manufacturing process requires a lot of time and effort. It’s impossible to make a forged element yourself. Masters gain experience over the years, so that after they make beautiful and durable elements that will attract the attention of others.

During production, ordinary metal becomes embossed, voluminous, patterned, acquiring the necessary shape and size.

Products of this type are the most expensive in comparison with other similar products. If you are looking for an original product for decorating fences, then only handmade forged parts will do. If you wish, you can order the product according to individual drawings.

Stamped products

Products of this type are made in large batches in factories. In this case, the originality is lost, but the affordable price allows everyone to decorate the fence with stylish metal parts. The most common elements: monograms, leaves, peaks, curls, racks, sockets, geometric shapes.

There are products in standard gray color, as well as treated with paint and other coatings.

They are created by casting. Molten metal is poured into the molds, which takes the necessary shape. Copper, gypsum, cast iron and bronze molds are used. This production method allows you to produce large batches, satisfying the needs of customers. Given the popularity of metallic decorative elements, there is always a demand for them.

Combination Options

Fences of various types complement metal inserts. The most common models:

- Wooden fence.

- Fencing from the profile (profile pipe).

- Fence from profiled sheet and corrugated board.

- Brick fence.

- Metal constructions.

- Designs made of artificial and natural stone.

The most popular ones should be considered in more detail.

Wooden

The combination of wood and metal looks stylish and expressive. Two completely different materials in contrast emphasize and complement each other. Warm, soft wood and cold hard metal are in perfect harmony.

Forged elements will not only decorate, but also increase the reliability, stability and practicality of the fence. Gilded elements will ideally combine with a tree in a saturated warm color.

On a light array dark metal details are more noticeable.

Products of this type will be an excellent decoration of the territory in the country style.

If the house is sheathed with natural wood, a fence made of natural material with forging will be perfectly combined with it. Ideal elements in plant themes, as well as classic curls and monograms. Jewelry is placed on the top of the fence or on the canvas itself.

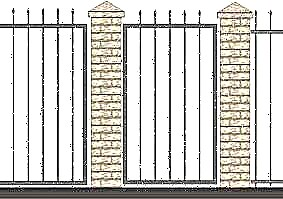

Brick

Practical, durable and reliable fences are made of bricks. Monolithic designs complement the sophisticated and sophisticated elements. Such a fence will protect property and possessions from illegal entry. Designers call this tandem the union of beauty and practicality..

The installation process of such elements is complex and time-consuming. For work, it is recommended to hire professionals who will securely fasten jewelry without damaging the fence.

Welded tops are actively used. They are fixed on brick poles and other parts of the fence. The shape of the optional parts may vary. Peaks and sharp tips are especially popular., which not only decorate the product, but also increase its height and make the process of penetrating the territory more problematic for attackers.

If you intend to install a brick fence on the site and then supplement it with forging, you must select the appropriate type of brick. Experts assure that it is very difficult to choose a suitable decorative component for a silicate brick fence.

Art forging looks best together with such material:

- Standard red brick.

- Shmatochny brick.

- Decorative and facing.

In a word - colored brick.

Metal forged fences

Forged parts can act as additional decorations or be a main part of the design. In the second case, metal grates decorated with forging are installed between brick pillars. Brick also serves as the base of the fence.

Fences made of metal attract customers' attention with a long term, reliability, practicality and high protection rate. Against the background of such canvases, classic forged elements and jewelry in a modern technogenic style look great. This option is the most expensive fencing, especially when you consider the cost of additional elements.

Jewelry is placed both throughout the canvas, so in certain parts of it. At the top, if desired, special tips are installed. Forged fences demonstrate the high status and sophisticated taste of the owner of the house. Fences of this type are excellent for arranging both residential and commercial premises.

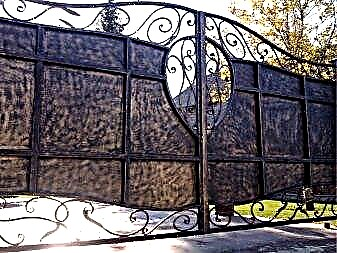

To cope with such a lack of forged fences as transparency, additional elements are used: polycarbonate sheets or corrugated board. However, some customers specifically opt for such structures because of their ability to freely let in air and sunlight.

Pros and Cons of Metal Fences

Like every decor element, forged fences have advantages and disadvantages.

Pros:

- Resistance to fire.

- Reliability.

- Long service life.

- Beauty and elegance.

- The ability to create a unique "live" composition with plants.

Minuses:

- The need for periodic corrosion treatment.

- Price.

- Difficulty in installation.

- The design does not protect against unnecessary noise.

Sketches of forged fences can be found in the next video.

What is forging

Depending on the method of creation, it happens:

- Stamped. It is done in production. It is an automated manufacturing process for metal elements. You can buy ready-made identical sections of the fence and install yourself. Much cheaper than manual, but such a fence will not be unique.

- Manual It is carried out by hot or cold technology. Each forged item is unique. The masters create custom-made whole pictures that can tell about the tastes and hobbies of the owners of the site. The process is laborious, time consuming. Finished handmade sectional sheets are an expensive pleasure.

Let us examine in more detail the manufacturing of parts by hot and cold forging.

Hot

The metal billet is heated to the desired temperature so that it becomes soft and plastic. Then the master with the help of a hammer, anvil or hydraulic press forms the part and cools it in cold water.

So they get exclusive elements of architecture, artistic ornaments and drawings. To speed up the work, many craftsmen purchase equipment on which it is practically not necessary to forge manually.

Cold

Not so popular. Workpieces are processed without heating. The shape of the metal is changed using a press, and then annealed. It is mainly used in the serial production of parts, grids using welding. Elements turn out beautiful, but not elite. But for a country fence - this is a good and inexpensive option.

Photo: cold forging with a bending machine

Photo: cold forging with a bending machine

Where is used

Forging is widely used both in the exterior decoration of buildings and in the arrangement of the interior. Most often, forging details decorate:

- stairs

- arbors

- fences, gates, gates,

- verandas, terraces,

- canopies

- window, doorways,

- balconies

- railings

- fireplaces

- chandeliers

- dishes, vases, candlesticks,

- arches

- barbecue facilities

- swing and more.

Photo: forging samples

Photo: forging samplesWith the elements in the form of tips, the peak forms the top of the hedges to give them a finished look.Monograms, currency, balusters adorn the railing of stairs, gratings of fireplaces, gates. Metal plants will beautifully complement the summer gazebo, balcony grill.

Wrought iron goes well with wood, polycarbonate, profiled sheets, steel, so many owners try to combine several types of materials during the construction of fences.

Classification by manufacturing technology

Fences are made in three ways:

- Connection of elements by welding. The cheapest option. Welded construction is not a work of art, but the fence will be reliable and accurate.

Photo: assembly and welding of forged elements in a single design

Photo: assembly and welding of forged elements in a single design

Often make fences in a third way. By purchasing ready-made sections, the owners significantly reduce the cost and time to build a fence.

Types of designs

- Fences mounted as separate spans and mounted on brick or stone supports. The posts are connected by a ribbon-shaped base with a height of 15–100 cm. A variant without it is possible.

- Continuous fence. Racks are steel pipes. With the right diameter, the design has a holistic look.

- Fencing with a fixed screen on which forged parts stand out. As a shielding surface, thin iron sheets, cellular polycarbonate, and corrugated board are used. Often this is the way the gate, gate for shading the yard and reliable protection from outsiders are drawn up.

Photo: stylish fencing of the local area

Photo: stylish fencing of the local areaIn order for the estate to be closed and not visible from the street, it is worth choosing a shielded fence.

Let us examine the design of other options for wrought metal fences.

Decorative (low)

They are used to decorate the site, and not to protect it. They have art elements. They are protected by flowerbeds, the garden area, the territory behind the house. They are made low - up to 1 m. They look elegant. They are painted in different colors. Made to order.

Photo: a combination of stone and metal in the fence area

Photo: a combination of stone and metal in the fence area

Protective (functional)

Factory imitation of art forging obtained by stamping. Implemented in sections. Popular types of pillars - brick, metal. Private properties, cottages, summer residences, parks protect such a fence. Often have a minimum of decorative elements. Very durable, provide reliable protection for the site. The price is affordable.

Combined

This structure combines elements of the first two types. The welded fence is complemented by simple forged parts. A polycarbonate screen and corrugated board are installed in the background. Standard parts are obtained in the factory by stamping. Such a fence is reliable, has average prices, attractive appearance.

Photo: forged fence is supplemented with profile sheets hiding the garden area from prying eyes

Photo: forged fence is supplemented with profile sheets hiding the garden area from prying eyes

In the private sector, a gate, a gate for a forged fence is often made out by a combination of materials.

Advantages and disadvantages

Pros of forged fence:

- Strength. The reliability of the metal can not be compared with wood or plastic. Forging can withstand any load, resistant to mechanical damage.

- Durability. The service life of such fences can reach one hundred years. Not for nothing that many of the historical monuments that have survived to this day have forged details. An important condition for long-term operation is high-quality corrosion treatment.

- Does not need special care.

- Repairable without harm to the entire structure.

- Beautiful patterns, ornaments look very expensive and elegant.

- Safety guarantee. Metal structures can be classified as burglar-proof. They are difficult to overcome, especially if the top of the fence is decorated with sharp peaks or tips.

- A wide selection of styles. To install budget fences, ready-made sections are bought. To get a unique structure, you should develop your sketch and order forging from the master.

The disadvantages are as follows:

- The price of art forging of individual models of fences can reach 50,000 rubles. for 1 square meter.

- The heavy weight of structures complicates their transportation, installation.

- To mount such a fence yourself, you need experience in construction.

- Fencing without shielding is almost transparent. Therefore, everything that happens on the site will be well visible from the street.

- Once every 3-4 years, it is recommended to treat the metal surface from corrosion. So it will last even longer.

If this is your first time encountering the process of building a fence, it is best not to experiment with self-installation, but to order the services of craftsmen.

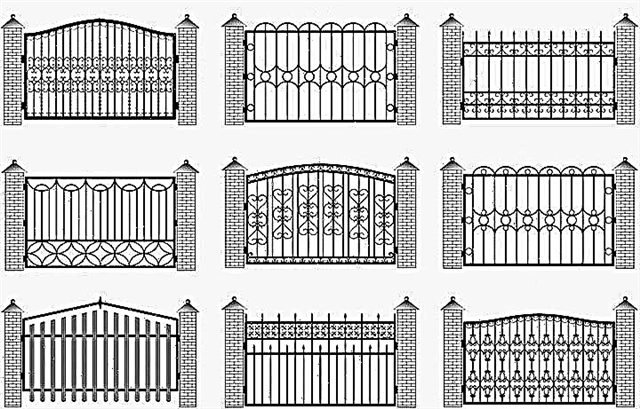

Schemes and drawings of finished structures in different styles

To put into practice any of the patterns, it is necessary to develop a sketch of the future section in advance. The drawing is selected based on the preferences of the owners, the design style of the structure.

Photo: various options for fence sections

Photo: various options for fence sections

Forging styles are enough to choose from. Let's analyze the main features of the most popular of them. It:

- Russian Convex elements are applied. Patterns are created with natural motifs.

- Russian-Byzantine. Very similar to the previous one. Parts are also convex. Decorated with floral ornaments. But the main difference is that the composition is complemented by geometric figures.

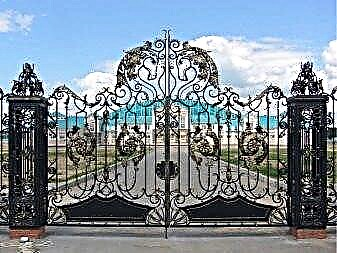

- Baroque The fence is saturated with small patterned details. They can be flowers, baskets, crowns, figurines, ornaments of ornate forms. All these elements create an overall picture of luxury and sophistication.

- Gothic. The fence is an elongated shape, directed to the sky. Often, the lancet arched structure, which looks very impressive, becomes the main detail.

- Rococo. It is a continuation of the Baroque, but it has much less small details. The main emphasis of style is elegance.

- Modern. Forging is saturated with abstract elements, evenly or unevenly spaced curved lines.

The style of the fence should be chosen in accordance with the overall picture of the architectural structures on the estate, so that it harmonizes with the whole composition.

Kovart

Experience in the field of forged products - 17 years. The skills of designers and craftsmen allow the use of artistic techniques that were used by blacksmiths in imperial times.

The company provides the following services:

- creation of drawing projects by order,

- metal shot blasting,

- 3D modeling

- laser cutting

- art patination - applying silver, copper, gold,

- chrome plating

- gold plated forged products.

Photo: an elite product made by Kovart

Photo: an elite product made by KovartThe list of products includes elements of the interior decoration of the premises and details for the exterior decoration of buildings, fences.

KovArt also implements in practice the sketches proposed by customers.

Rowand forging

The domestic company was founded in 1997. Makes welded, forged structures of various complexity and sizes:

- goal,

- railings

- visors

- ritual fences,

- furniture,

- fence sections and more.

It is taken for any amount of work to order.

Kreytmet

Russian factory. Mainly produces plastic, metal-plastic, forged products.

The volume of technical capacities of Kreitmet allows producing up to 200 tons of metal structures per month.

- square, round profile fences,

- hinged and sliding forged, welded gates,

- forged, welded window grilles,

- railings

- flower girls, coasters,

- visors

- chandeliers, sconces.

In addition to the release of goods to order, a team of craftsmen performs installation work.

Insight

The plant is engaged in art forging. Has production workshops in Moscow, Voronezh, St. Petersburg. It produces decorative elements, fences, furniture, lamps and more. Designers will help to develop a design sketch according to the idea of the client or an individual project.

Necessary materials and tools

To install the fence you need:

- wooden pegs, rope,

- level,

- shovel or drill

- roulette,

- plumb

- a grinder with a disc for metal,

- welding machine, mask, electrodes,

- cement, sand, gravel,

- material for pillars,

- hammer, file,

- anticorrosion primer,

- paint,

- spray gun, brush.

The territory is cleared of vegetation, garbage. Along the perimeter of the future fence, marking is performed. In the places of the columns pegs are driven in increments of 2.5 m, a rope is pulled between them.

Foundation arrangement

There are several options for the base for forged construction:

- Pouring monolithic concrete tape.

- Columnar and dotted foundation for each rack.

- Pile-screw (on swampy soils).

The first two are used more often. Under massive fences with brick, stone pillars fill the tape, under lightweight fences - columnar foundation.

We will analyze the main stages in the creation of these bases.

Columnar

Concreting of each support is carried out separately in a previously prepared well.

The procedure is as follows:

- Dig holes under the posts or drill them to a depth of 0.7–1.5 m. The recommended depth is a minimum of ⅓ the height of the future support. Diameter 25-30 cm.

- The bottom is rammed. A metal stand is put into the well according to the level. Another option is to fix pieces of asbestos-cement pipes in the wells so that they are 10-15 cm high above the ground. The empty space around is filled with crushed stone, liquid concrete mortar. The metal stand is fixed on top.

Builders do not recommend to completely concrete the pillar until a section of the fence is welded to it, because if at least a centimeter is lost with a step between the supports, it is hardly possible to accurately fix the spans.

Tape

The column foundation, supplemented by a continuous concrete strip, will increase the rigidity of the structure and significantly extend its service life.

Photo: installation of a strip foundation for a fence

Photo: installation of a strip foundation for a fence

To do this, in the prepared trench, wells are drilled under the pillars. Knock down formwork from wooden boards. Supports are inserted into the pits, set on the level. The trench is reinforced. For reliability, the reinforcing frame can be welded to the posts (if the supports are metal). To the ground level, everything is poured with concrete. Hardening time - up to 3 weeks.

Pillar Installation

For forged sections, several options for supports made of different materials are suitable:

- Metal. Easy to install. Often, they take profile pipes of round, square or rectangular cross-section (40 * 60, 50 * 50 mm). Durable They withstand loads. It is recommended to close the top with a lid, welding it to the pipe so that moisture does not enter the pipe cavity. You will read about the selection, processing and stages of their installation here: "Metal posts of metal."

- Brick. Perfectly combined with forging. For racks, a facing brick is purchased, from which columns are laid. The foundation is a monolithic tape with a depth of 1 m. The masonry is reinforced, so the ordering is carried out around an installed metal pipe 40 * 40 cm. The recommended support height is from 2 to 2.5 m, the cross section is 1.5 bricks. For securing the sections in the brick, special mortgages are fixed, to which the spans are then mounted. Recommendations for choosing the type of brick, masonry, the order of construction of pillars you will find here: "How to lay out pillars for a fence from a brick."

- Asbestos pipes, concrete racks. Easy to install. No protective treatment or maintenance required. Looks good in combination with forged grilles. Reliable. Durable But they should not be bought for fences more than 1.5 m high.

When installing the fence yourself, it is better to choose metal poles, since their installation process, attaching to spans will be easier and faster than in the case of brick, concrete poles.

Section Mounting Methods

- By welding. Lattices are simply welded to the posts. More popular mount. Suitable for metal supports.

- On the fasteners. It is carried out with brick, concrete supports, in which embedded parts are pre-mounted. On the nut-bolt connection, you can also mount sections to metal posts.

An alternative is to grout the fence sections into a concrete base.

Photo: fence installation process

Photo: fence installation process

Regardless of the material for the pillars, their top should be protected from constant exposure to rain. To this end, decorative caps are mounted on top, which prevent water from entering the inside of the column.

Installation of a gate and gate

When using metal poles, the procedure is simplified, because they simply weld hinges on which the gate leaves, gates are hung.

In the case of brick, stone or concrete racks, it is worthwhile in advance, even at the masonry stage, to lay mortgages in them - thick rods of reinforcement. At the same time, it is important that the reinforcement is not installed strictly horizontally, but at an angle of 45 degrees, and the lower edge, looking outward, looks down. The reason is simple - during operation of a heavy gate, the center of gravity is constantly shifting and the location at an angle will not allow the gate to sag, skew.

Photo: forged gates

Photo: forged gates

The outer piece of reinforcement is cut off, leaving 1 cm so that metal loops can be welded. When the hinges are firmly fixed, the gate leaves, gates are hung.

It should be noted that for the doors to open freely, the distance from the bottom of the canvas to the track should be at least 5 cm, at least 1 cm on the sides of the pillar.

At the end of construction work, all welds are cleaned, degreased.

Painting

A protective anti-corrosion primer is applied to the prepared metal surface, sometimes in several layers. Drying time is one day. Then they paint the fence.

A detailed list of suitable protective equipment, their application technology can be found in the article: "Painting a fence made of metal."

The processing of the forged surface is complicated by the presence of small parts, so when using a spray gun there is a high risk that many areas will remain unpainted. For hard to reach places it is better to take a brush.

Dressing

Each era has made its own changes in forging. Popular elements today are:

- curls, snails,

- climbing plants

- broken lines

- waves

- sharp peaks

- arrowheads

- flower baskets and more.

Photo: caps on brick pillars with lanterns and forged elements

Photo: caps on brick pillars with lanterns and forged elementsTo emphasize the beauty of art drawings, a live green hedge is created along the perimeter, the branches of which harmoniously braid the iron bars of the gratings.

It is possible to achieve the effect of antiquity and luxury if you patinate forging - due to the special paint you can get an imitation of antique metal with a touch of gold, bronze or silver.

Well complemented by a fence of brick columns and wrought iron gratings, lights mounted on top of pillars. They look beautiful and improve the illumination of the site.

Forged fences in skillful hands are transformed from ordinary protective structures into works of art that, in addition to standard functions, delight owners and others with their sophistication and beauty.

The advantages of forged fences

Forged fences find their application in many places. The design is popular for its combination of physical strength and visual lightness. To assess the versatility of forged sections of a metal fence, you need to familiarize yourself with its advantages:

- High level of reliability. Thanks to manufacturing technology (metal is hardened several times), the fence becomes resistant to adverse weather conditions and mechanical damage.

- Durability (serves for many years).

- Security.The hardened metal has high strength, so it is not easy to damage the material. In addition, a large number of interwoven rods, sharp tips and small elements preclude the penetration of intruders.

- Aesthetic appeal. Many products are exclusive and are made to order. Fences with forging elements look original and beautiful.

- Easy care. It does not require constant cleaning. There is no need to dismantle the structure to remove scratches or rust.

- A wide range of. A wide variety of species allows the installation of protective, decorative (art forged fences) and combined metal gates.

- Harmonious combination with any style of construction.

- Resistance to corrosion and fire due to powder coating or galvanizing.

Forging on any fence can be made according to an individual sketch, thereby giving uniqueness and difference from typical fences.

A beautiful forged fence is the hallmark of a suburban area

The service life of forged fences is estimated at decades and even centuries, subject to timely updating of the protective coating

What is important to consider before choosing a forged fence

First of all, when choosing forged products, you need to consider the goals for which they will be used. To choose the right option, you must consider the following:

- Construction height. The optimal size is 2.5-3 m. The higher the section, the more protection it provides. A too small fence (not higher than 1.5 m) most likely performs only a decorative function.

The fence with a forged top on a stone base looks reliable and neat

The photo shows examples of forged elements for the fence of the garden

With the help of hand forging, unique elements are created that make up original paintings that can tell about the tastes of the owners of the site

The weld must be of high quality. In places of welding there should be no bumps, cracks and voids.

Assembling forged elements in the intake section by welding

Design features forged fence

A metal fence, decorated with an original design idea, will be an adornment for any country house. Various ornaments, flowers, snails and other metal elements have become an integral part of forging, as art. Interesting options forged fences are presented in many photos.

The simple wrought iron fence looks restrained and solid

Forged fences are made out not only with patterns, but also with colors. At the same time, the color palette is very diverse. You can pick up fences, the forging of which has exactly that shade, which harmoniously fits into the general appearance of the site. You can add a noble retro effect by patinating sections. Gilding looks interesting and rich.

Patination and gilding add chic and presentability to the fence

Forged fence on a high brick base - a compromise between the protective and aesthetic properties of the fence

Stylish design effect is achieved by combining metal and brick. These two materials are organically combined and complement each other. Add a product of decorativeness and stability. It is carried out in several options:

- Fence with brick pillars. The classic version, where the main part is metal spans. Can be with or without a brick base.

- Equal ratio of brick and metal. At the same time, the lower part of the fence (1-1.5 m) and the posts are made of brick, and forged elements are located between the columns.

- Fence with semicircular forging. The most interesting and artistic option. The lower part (1-1.5 m) and pillars are laid out of stone, and the spans are presented in the form of semicircular sections of metal elements.

The combination of natural greenery and metal not only improves the aesthetic appearance, but also perfectly isolates the territory. A hedge of climbing plants, braiding an iron lattice, favorably emphasizes the infield.

The forged fence twined with flowering plants looks elegant and beautiful

The most popular solution is decorating with wrought iron lamps. This design gives the designer completeness to the product. An additional element will make even the simplest option memorable. There are two ways to post:

- at the top of the fence post, in the form of a pommel (lights are welded on the leg),

- wall or pendant lights (fasteners are carried out on the supports on the side).

The use of cast elements gives volume and vivid detail to the products. Decorative decoration is made in the form of overlays or tops on fence posts, thrust bearings, balusters, rosettes and bas-reliefs, metal flowers, leaves and small sculptural forms.

Using forging, you can make a variety of compositions of any style (classicism, gothic, baroque, empire, etc.). Mixing different styles is appropriate. To determine the style, you can pre-familiarize yourself with photos of interesting options forged fences.

Baroque fence decorated with small patterned details.

Classicism style fencing requires poise and integrity. For the construction, rods with spears in the upper part are suitable. This style involves the use of patterns of complex shapes.

Sharp peaks at the top of the classic fence will serve as a warning to uninvited guests

For fans of the Gothic style, wrought-iron gates, characterized by sharp and strict lines, are suitable. They are dominated by ornamental floral patterns.

Gothic forged luxury fence

The most popular Art Nouveau style. There are no straight lines in it, preference is given to plastic forms, bends and curls. Oriental ornaments and abstract compositions are also relevant.

Art Nouveau forging is distinguished by smooth lines and a saturation of abstract elements

Oriental-style products are complemented by painted elements.

Design options - photos and diagrams

With all the variety of drawings, patterns, shapes and decorative elements, forged fences are customarily made according to the most common patterns. Such limitations are explained by the production method and metal processing technology.

A wide variety of forged fence patterns allows you to choose the most suitable option for your site

The combination of stone, forging and wood looks original

Forged fences, photo schemes of which can be viewed before ordering, are performed as:

- Separate spans. It is made out by brick or natural stone. Supports can be made according to a foundationless scheme or connected by a base with a height of 15 to 100 cm.

- Continuous web. The fence is mounted on steel tubular supports. The diameter of the posts is small, so the entire canvas of the forged fence looks like one continuous span.

- Steel sections with a screen. Most often, shielding is used to protect or obscure the surrounding area. Basically, a sheet metal or cellular polycarbonate is taken to install the screen. Corrugated board is also suitable. The closer the fence is to the house, the larger should be the shielding surface.

Forged fence, supplemented with profile sheets, will hide the yard from prying eyes

When planning sketches, it should be borne in mind that in the manufacturing sector there are established forms, styles and design ideas. A cardinal deviation can ruin the aesthetic appearance of the product.

There are countless design options for forged sections, here are just a few of the most common schemes:

Pillars

Creating a forged fence begins with the manufacture of a durable, reliable and high-quality base. As a support can act metal rods and pipes, as well as brick.

Compound poles of several metal rods possess following benefits:

- high stability and strength,

- long service life

- the ability to create a fence of various heights and configurations,

- ease of installation and installation.

As a support, metal pipes (for example, twisted) can act. The base of this kind has own advantages:

- resistance, strength, durability,

- simplicity and speed of installation,

- reasonable prices for pipes,

- it is possible to perform fences of non-standard options.

In the photo on the right, such poles from the company Siberia Metal Design.

A combination of forging and brick is popular with customers. Decorative forged patterns on the fence and the universal properties of the stone make the design an almost perfect option for fencing. The advantages of this type of bases and other interesting information will be presented in a separate article.

Lattices (sections, grids)

The assembly of the fence can be carried out directly at the installation site. However, a more convenient and common option is the finished forged sections of the fence. Contractor creates sections of the necessary sizes. At the customer’s site, the grilles are attached to the poles and a reliable fence is obtained.

The assembly of the fence can be carried out directly at the installation site. However, a more convenient and common option is the finished forged sections of the fence. Contractor creates sections of the necessary sizes. At the customer’s site, the grilles are attached to the poles and a reliable fence is obtained.

In addition, customers have the opportunity to order highly artistic forgingwhich is executed manually. However, forged products of this kind are notable for their high prices. An alternative is sections welded from parts created in accordance with cold forging technology. These forged items are sold at lower prices, affordable to everyone.

Than paint

Painting is the final step in the manufacture of forged fences. The appearance of the products and its service life depend on which type of coating to choose. There are a large number of different coatings on the market. Therefore, it is sometimes difficult to choose the optimal composition. Therefore, it is very important to know what is better to paint forging.

Painting can be done special paints, the main types of which we consider below.

Powder paint is a dispersive multicomponent mixture of solid particles in the form of powder and air. Powder spraying is carried out in special furnaces, which limits the size of the processed product. In addition, this type of coating is suitable for smooth surfaces. Therefore, bizarre fence elements can be difficult to paint.

Powder coating is characterized following benefits:

- high protective and decorative properties,

- wide color gamut

- lack of smell

- fast hardening of the coating,

- lack of need for the use of solvents that are toxic and flammable,

- durability,

- affordability

- even thickness of paint layers.

The furnace for painting, photo “Metal Melody”

The main disadvantage - the availability of special equipment for coating. In addition, the contractor may have problems with processing non-standard shape products and prefabricated structures.

Hammer paint It is a nitro-based polymer dye. After drying, the coating acquires an original appearance - potholes of different sizes resemble traces from a blacksmith hammer strike on metal.

Hammer paint It is a nitro-based polymer dye. After drying, the coating acquires an original appearance - potholes of different sizes resemble traces from a blacksmith hammer strike on metal.

To apply a similar coating on a metal surface, special equipment will not be needed, so processing can be done independently.

Advantages hammer paint:

- lack of need for applying a primer,

- very strong adhesion of paint to metal,

- resistance to moisture, ultraviolet and mechanical damage,

- durability.

disadvantages hammer paint:

- high price,

- the difficulty of removing the coating

- a large number of fakes.

Water-dispersed paintsincluding acrylics are also suitable for painting forged fences.

Advantages paints of this type:

- low toxicity

- the coating does not spread, does not crack, withstands temperatures up to +120 degrees,

- moisture resistance

- high adhesion of paint to metal.

Only significant disadvantage is burnout from ultraviolet exposure.

Emulsion paints: alkyd and oil - suitable for external and internal work, give the product a glossy look. Oil paints are rarely used for processing forged fences, as they quickly fade and poorly protect against corrosion. Alkyd coatings are well suited for forged surfaces, have the following advantages:

- sustainability environmental influences,

- getting deep and rich colors.

The main limitations: paints dry for a long time, toxicity.

Nitro enamels have undeniable advantages: affordable price and quick drying. However, the high toxicity and combustibility of the product became the reason for the displacement of paint from the market.

Patination (patina) - A popular technique for metal processing, as a result of which the workpiece is artificially aged. Such a coating has the following advantages:

Patination (patina) - A popular technique for metal processing, as a result of which the workpiece is artificially aged. Such a coating has the following advantages:

- protection against damage and corrosion,

- resistance to deformation,

- product decoration, color change.

How to paint

The product may be painted on site, also blanks for forged fences can be processed in advance. In the first case, the coating should be carried out in dry and calm weather, the air temperature should be + 18-35 degrees. During drying, the product should not be exposed to direct sunlight. These requirements are not always feasible, so it is better to paint forged objects in advance.

For painting use various tools: brush, roller, spray gun, spray gun (pneumatic or electric).

Elements of forged products of complex shape should be painted brush. You should choose a quality tool, from a cheap brush, hairs that will remain on the painted structure will quickly start to come out. In places of bending and welding it is necessary to use a larger amount of paint.

Roller should be used for painting small and even surfaces. Paint should be poured onto the surface to be treated in small portions, which will allow you to get a uniform coating, without gaps. The workpiece must be horizontal.

Atomizer (atomizer) when painting should be kept at right angles. This position of the tool will provide an even coating, air flows will not blow off the applied paint. It is important to paint slowly, carefully observing uniformity.

Spray gun (spray gun) is the exact tool for painting. The rules that must be followed when working with the spray gun must be followed when applying the spray gun.

Items

Earlier, we listed and analyzed large parts for forged fences: poles and gratings. In addition, you should specify small items for fences. Forging for the fence is able to give the design a unique look.

Earlier, we listed and analyzed large parts for forged fences: poles and gratings. In addition, you should specify small items for fences. Forging for the fence is able to give the design a unique look.

Pillar caps

Pillar caps perform two functions: protection against precipitation and decoration, individualization. If the stubs are pointed in shape, they make it difficult to climb over the fence. A lighting fixture can be integrated into the forged cap.

Other fittings

Elements demanded by clients are:

Elements demanded by clients are:

- padsthat perform the functions of fasteners and decoration, are distinguished by a wide variety of shapes,

- bumps - decorative details that add sophistication and elegance,

- balusters - parts used as fencing fences, gates, railings, give stability and strength to structures,

- peaks - decorative elements used to decorate protective structures,

- curls - various in shape details used exclusively for decoration,

- baskets - openwork products that add to any forged object of aesthetics,

- leaves are decorative volumetric details, the appearance and texture of which resembles natural plants,

- the flowers - highly artistic items of a decorative nature, roses are especially popular with customers.

A complete list of items is presented on a separate page.

How to do it yourself

Our site provides a large number of informational articles that allow you to independently master the forging technique. Those who wish to get a professional education should familiarize themselves with the list of educational institutions. In addition, some companies and blacksmiths conduct workshops.

With proper and proper care, forged fences will serve the owner forever. Periodically necessary inspect the fence for rust. Corrosion must be immediately eliminated with the help of special compounds. Once every two to three years should be painted. This will preserve the original appearance and provide protection against rust. Movable, fastening and unlocking elements of the fence It should be periodically coated with waterproof grease, a regular auto grease is suitable.

Where can I buy

Almost all companies working in the forging industry offer a wide selection of ready-made elements for the fence. In addition, the masters of enterprises are ready to create a unique design fence. We offer you to familiarize yourself with the full list of forges and professional performers making fences, which are presented in a separate section of our catalog.

Forge “Stalhof”, Kaliningrad, photos of works and 5 facts about the company

Kaliningrad blacksmiths sent photos of their work, in addition, they sent information about the company. Photos of the forged stairs, railings and railings (presented below) are placed in the photo gallery, the stairs section, company contacts are also available on the Kaliningrad page, in the blacksmiths catalog. According to Leonid Vigonyuk, the company.

Photos of forged works (railings, peaks, fences, etc.) from the smiths of Ufa

The blacksmiths from the capital of Bashkortostan, the city of Ufa, Boris Nikolaevich and Denis Borisovich sent a photo of their forging work. The work is excellent, below you can see 11 pictures of forged products, the smiths' contacts are located in the catalog, on the Ufa page. Also on this page under the photo, you can read how the blacksmiths presented themselves and what.

Forged fences (photo)

Forged fences are one of the best fencing options. Reliable, beautiful, durable and functional products are especially popular among customers. More detailed information is provided in the corresponding section of the site. This page contains photographs of this type of product. Catalog.